TM 5-3610-253-14

Table 5-6. TROUBLESHOOTING - Cont

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

4. UNDERCUT DURING THE CUT. THE KNIFE MOVES BACK INTO THE MATERIAL SO THAT THE TOP

SHEETS OF THE MATERIAL ARE LONGER - Cont

Step 2.

Check that material is not too soft for proper knife cut.

(a) Immaterial is too soft, increase clamp pressure.

(b) If malfunction persists, refer to organizational mainte-

nance.

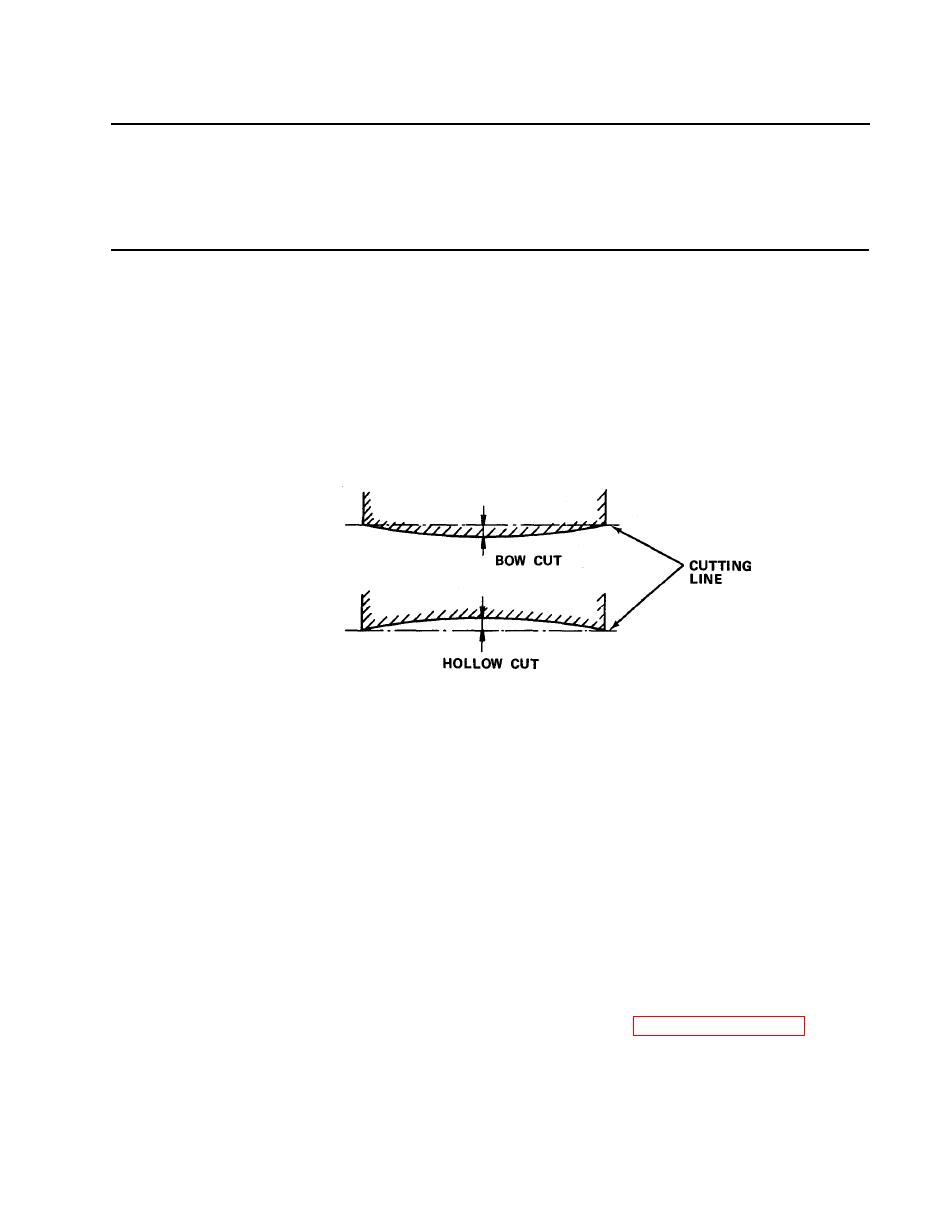

5. BOW OR HOLLOW CUT OBTAINED.

Step 1.

Check that material is properly jogged.

(a) If not, jog material.

(b) If jogged properly, proceed to step 2.

Step 2.

Check that material is even in height.

(a) If not, make material even in height.

(b) If material is even in height, proceed to step 3.

Step 3.

Check that material is not wavy or warped.

(a) Reduce the clamping pressure as far as possible and start

trimming the material from the center.

(b) If malfunction persists, refer to organizational mainte-

nance for replacement of the knife (paragraph 5-16.13).