TB 1-4920-443-35

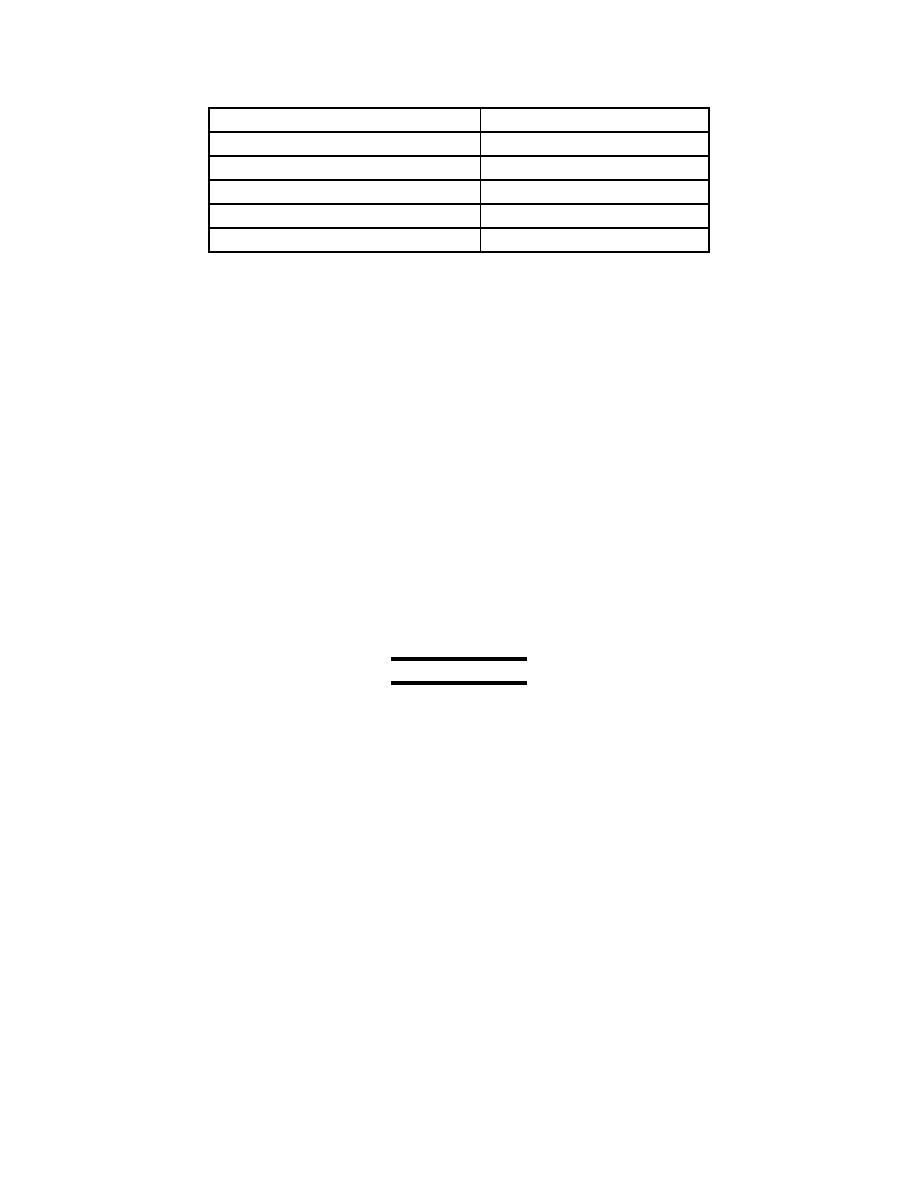

Table 50-2 TI Speed Indications

Input (Hz @300 mV p-p Rms)

Speed Indication ( .1%)

181.4 (20%)

272.1 (30%)

453.5 (50%)

725.6 (80%)

907.0 (100%)

51. Torque, RPM, and Horsepower Indicator System

a. Performance Check (T700)

Engine/Dynamometer Limit Control Panel modules to warm-up.

(2) Depress the TI Channel Caller channel #0 pushbutton. Ensure the TI Strain Gage Conditioner digital

indicator is in the foot-pounds display mode.

(3) Depress both TI Strain Gage Condition Filter Hz pushbuttons (insert 0.2 Hz filter).

(4) Adjust the Balance Coarse or fine control until the digital indicator displays a minimum value.

(5) Verify that the TI Strain Gage Conditioner digital indicator displays 0.0 2.0.

(6) At the engine test trailer, install the transducer torque arm and pan (supports the alignment weights)

on the torque tube.

(a) Apply upward movement to the torque arm and verify the TI Strain Gage Conditioner returns to

zero.

zero.

(c) Adjust the Balance Coarse/Fine control until the digital indicator displays a zero value. Note Old R

CAL value:_________. Add 100# weight, display indicator displays 200 2.

(7) Add an additional 100 pounds of alignment weight to the transducer torque pan.

CAUTION

Visually inspect the threaded portion of the weight hanger rod for cracks or stripped

threads.