TM 5-6675-328-14

Table 5-1. OPERATOR PREVENTIVE MAINTENANCE CHECKS AND SERVICES - Cont

B - Before

W - Weekly

AN - Annually

(Number)-Hundreds of Hours

D - During

M - Monthly

S - Semiannually

A - After

Q - Quarterly

BI - Biennially

ITEM TO BE INSPECTED

For Readiness

ITEM

IN-

Reporting,

NO.

TER-

Equipment Is

VAL

PROCEDURE

Not Ready/

Available If:

FILM PROCESSOR - Cont

12

W

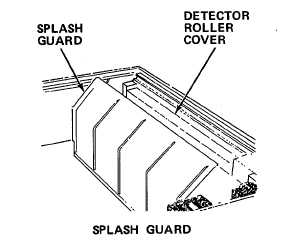

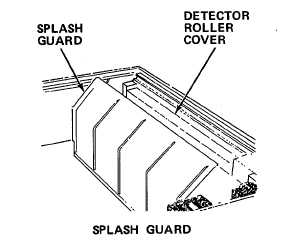

Service Transport System - Cont

1.

Remove top cover and all crossover assemblies.

2.

Remove wash rack, fixer rack, and developer

rack assemblies from processor.

3.

Clean all assemblies and crossovers with

sponge and warm water to remove chemical

deposit buildup.

4.

Inspect gears for broken or chipped teeth.

Gears broken or

teeth chipped.

5.

Be sure rollers turn freely.

6.

Inspect all rollers for damage.

7.

Clean all solution tanks with sponge and

warm water to remove chemical deposits.

8.

Reinstall rack assemblies in processor.

Make sure that gears properly engage in

worm drives.

5-34