TM 5-3610-253-14

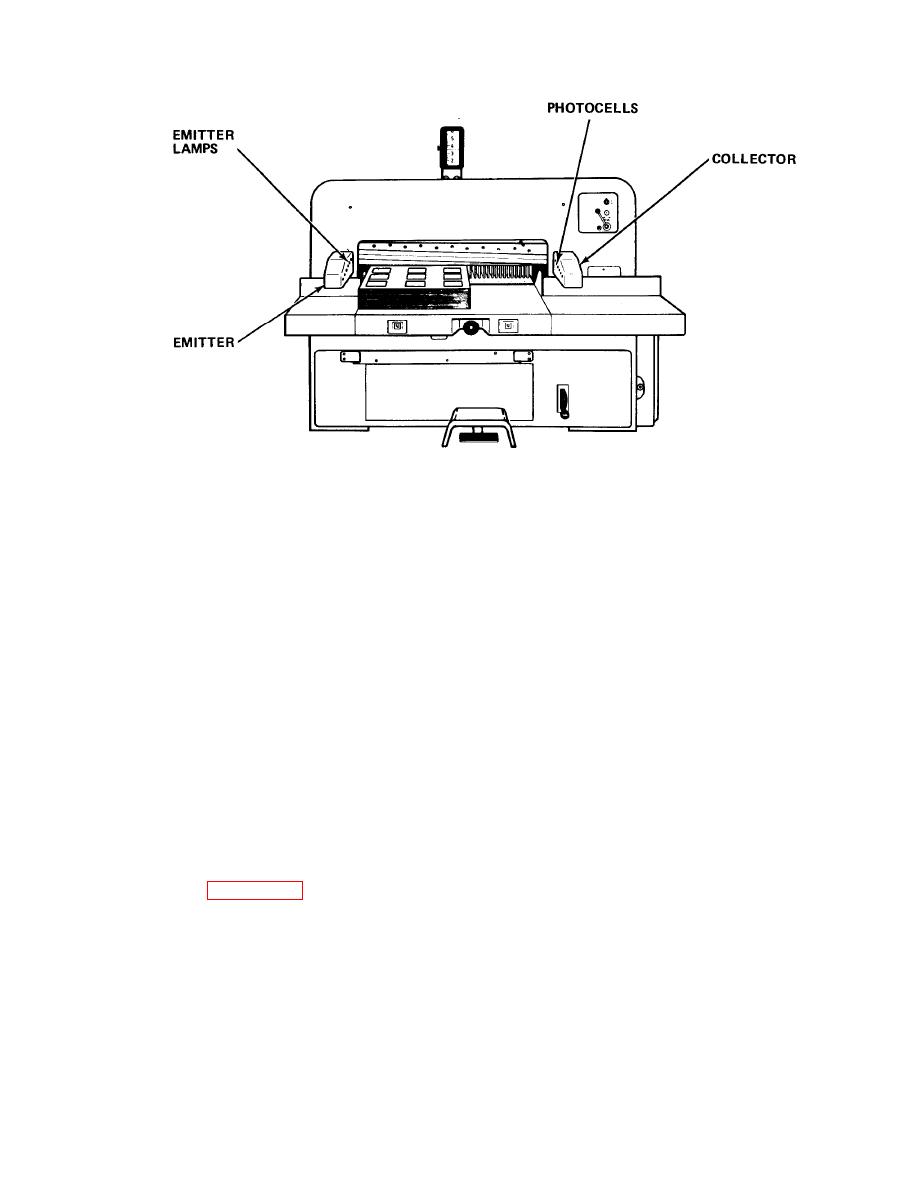

(1) Emitter. Contains an array of six lamps and lenses. A lens is mounted

in front of each lamp to focus the light transmitted by the lamp. The transmitted

light is directed toward collector across cutting area of the table. The lamps are

mounted on adjustable spring bases so the intensity and direction of transmitted

light can be adjusted. A relay board (LSL) is mounted in the housing to control the

operation of the emitter lamps.

(2) Collector. Contains a set of photocells mounted on the photo element

board (LSF), and lenses, arranged opposite transmitting lamps. The photocells

collect transmitted light, focused by lenses, to create sufficient voltage to cause

a transistor stage on light barrier PC card 9 to become conductive towards a O-logic

voltage level. The photocells are switched in pairs. A separate signal lamp in

the collector indicates when all the photocells are receiving light. If operator

reaches across table toward knife, one or more light beams are interrupted, causing

the voltage level in the collector cells to raise. This results in a logic-1

voltage (2.5 V dc) in card 9 (test point 9R4), which de-energizes relay d37 powering

the signal lamp and causes the hydraulic clutch on the main drive motor to disen-

gage, engaging the spring-activated brake and stopping the knife during downward

motion. Before each cut is performed, the condition of light barrier collector

automatically is tested to ensure no beams are being interrupted. The photo element

board has three test points, G1, G2 and G3, used to check voltage output of

photocells. Table 5-1 shows voltage values that should be received if a light beam

is interrupted.

5-17