TM 5-3610-253-14

(2) Control transformer. Has input taps for adjusting to multiple voltages.

The primary winding has tap connections for 180, 200, 220, and 240 V. The taps on

the secondary windings provide voltages of 12.5, 6.2, 5.8, 9.5, 7.2, 6.5, 25, 32,

42, 50, and 220. Total power output of transformer is 500 W. The control

transformer supplies power to other components in the system via a standard

control (ST) PC in the electronics enclosure.

(3) Control power on relay

(d304). Coupled with the control power on switch

(d292), the control power on relay

controls the application of power to the control

transformer. Pressing the control

power on switch energizes the relay, which closes

its N.O. contacts and allows power

to flow to one side of the control transformer.

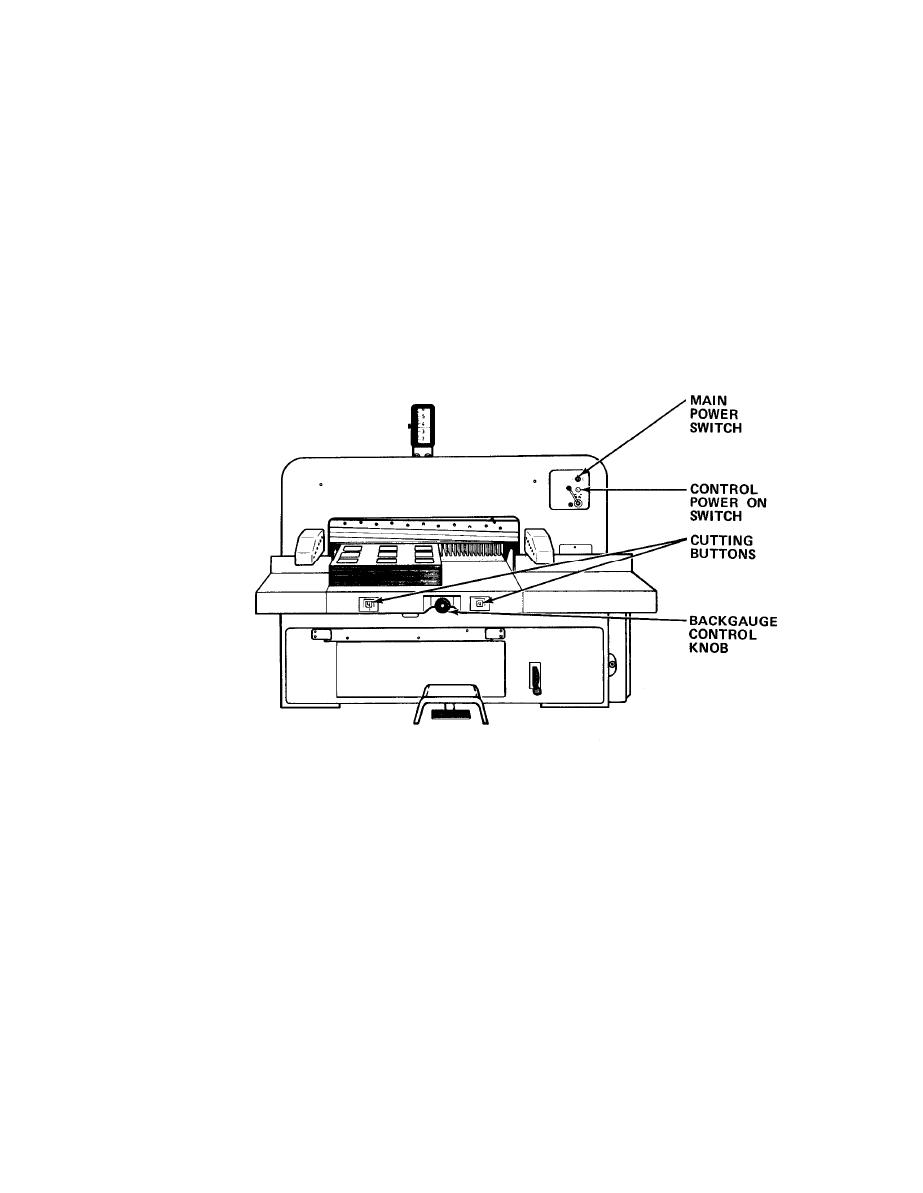

c. Operating switches. Provide operator control of the system. There are

six operating type switches:

(1) Main power switch. Primary power switch. A three-pole direct switch

that applies power to the main drive motor, fluorescent lamp switch, contractors con-

trolling the backgauge motor, and the control power on switch.

(2) Control power on switch. Energizes the light barrier and the PC cards

in the electronics enclosure via the control power on relay. Activation of the PC

cards enables operation of the hydraulic system solenoids. Power cannot be applied

to the control power on switch unless the main power switch is closed.

(3) Cutting buttons. Controls the knife, via the hydraulic system. Pressing

both buttons within 0.5 seconds applies power to the contractors and relays con-

trolling operation of solenoids in the hydraulic system control block.

5-15