TM 5-3610-253-14

(1) Main drive motor. Provides power to the hydraulic pump, and the hydrau-

lic clutch and gear assembly, via three' pulleys and two V-belts (the clutch and gear

assembly drive the knife). It is controlled directly by the main power switch

on the control panel. It continues to run as long as the main power switch is in

the "I" (on) position. The main motor has a high stalling torque, so that when

materials have to be cut, rpm of the motor will drop but the knife will be pulled

through the material without fluctuating. An overload relay, located under the

cutting table, directly above the right pillar, protects the main drive motor from

an overload.

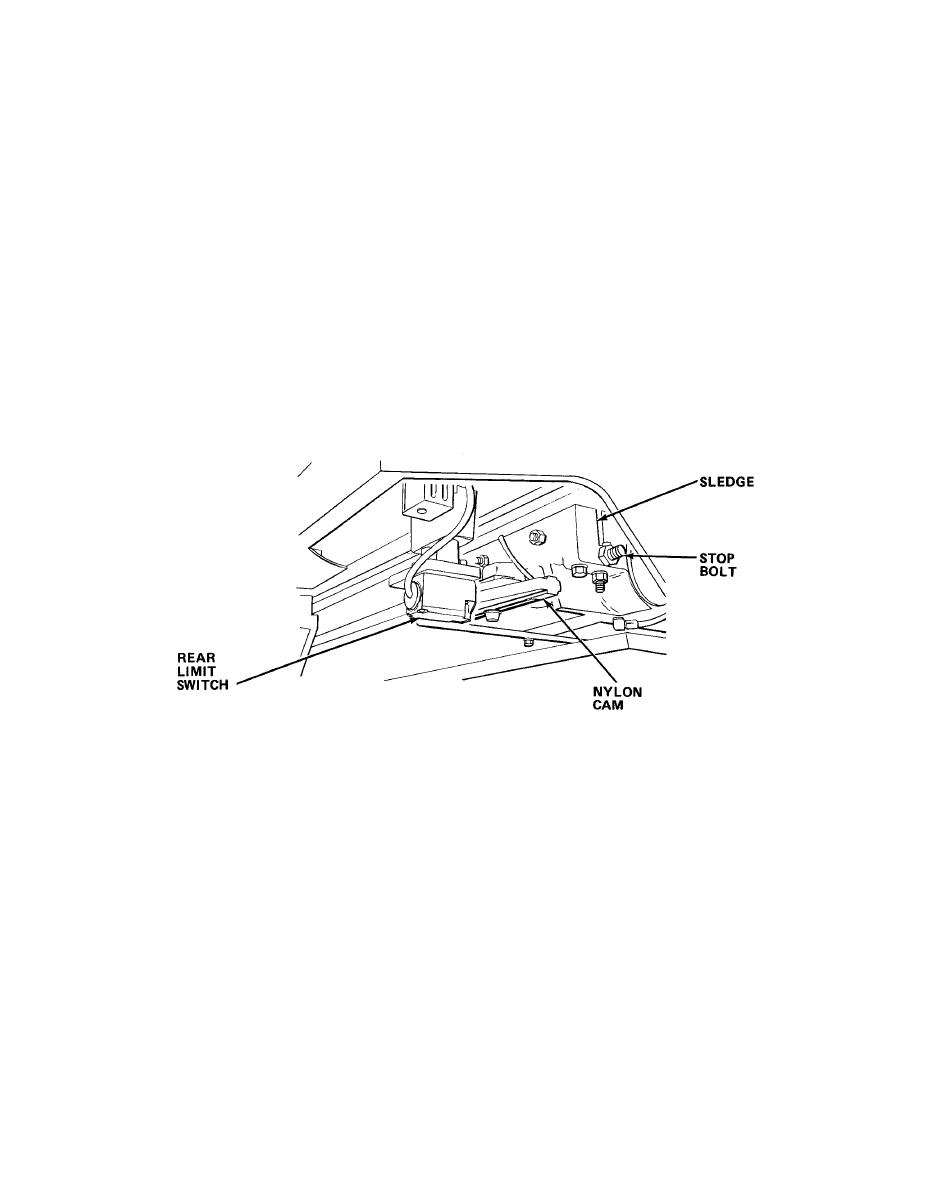

(2) Backgauge motor. Provides power to the backgauge carrier via a pair of

pulleys and a V-belt. Operation and the direction of rotation of motor is control-

led by a pair of contractors c12 and c15 on standard control PC ST, limit switches

mounted along the table bed, and backgauge controls. Power is input from the

control transformer. When not in use, the motor is off. When contactor c12 is

energized by the backgauge control circuit, the N.O. contacts close and the motor

runs forward. If c15 is energized, the motor runs backward. Limit switches mounted

along the table bed where the backgauge runs limits the distance the backgauge can

travel in either direction. The switches are activated by a pair of nylon trip dog

cams that ride on the sledge.

When activated, switches cut power to motor. Switch b13 limits (i.e., is activated

by) backward travel. Two switches, b8 and b9, limit forward travel. The first of

these switches, b8, can only cut power to motor if false clamp has been removed from

its mount, activating limit switch b6 on which it rests. Switch b8 is used to limit

backgauge travel shorter than normal to provide the extra space needed to mount the

false clamp. The backgauge motor is protected by an overload relay. The relay is

located under the backgauge table on the back of the support brace.

5-21