TM 11-5855-261-23

CHAPTER 4

DIRECT SUPPORT MAINTENANCE INSTRUCTION

Section I. General

Tools and repair parts required for direct support

4-1. Scope

maintenance are contained in Appendix B. Section I of

Direct support maintenance consists of tests, inspec-

the MAC, and the repair parts and special tools List

t ions, troubleshooting, and replacement of assemblies

(RPSTL), TM 11-5585-261-23P.

and parts. This category of maintenance does not re-

quire use of shop equipment or complex procedures.

4-3. Lubrication

Authorized direct support maintenance is listed in the

The O-rings for the electronics assembly and the refrac-

maintenance allocation chart (MAC), Appendix B.

tive lens assembly required lubrication. Use O-ring

Direct support maintenance is done at a maintenance

lubricant (MIL-S-8660) or equivalent. (See Section III

shop, or van, remote from field operations. At that

for removal and replacement procedures. )

Location, the failed assembly is replaced and the

repaired unit is returned to service.

4-4. Consumable Items

4-2. Tool Requirements

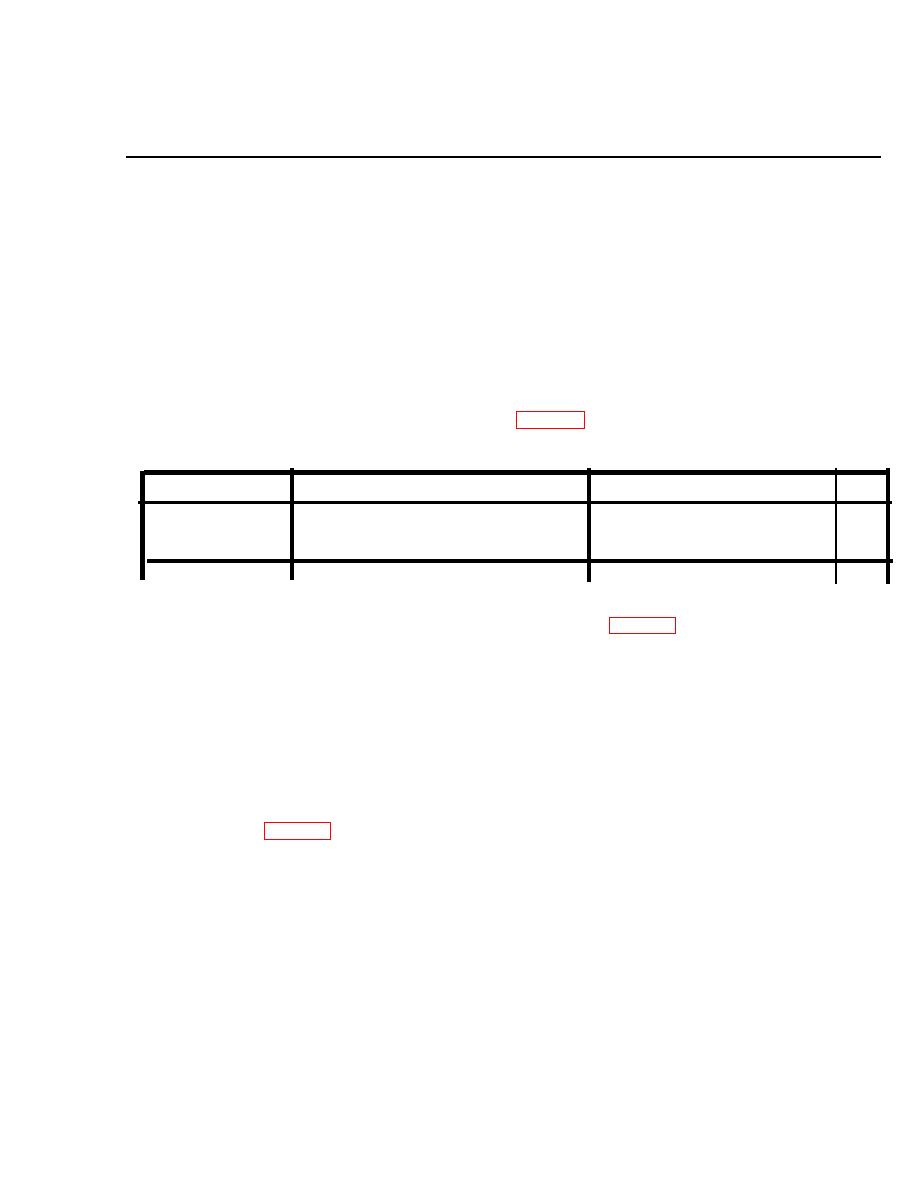

Table 4-1. Consumable Items

U/M

Identifying Part No.

NSN

Item

cn

Lubricant

MIL-S-8600

pk

Lens paper

NNN-P-40

Section

Il.

TROUBLESHOOTING

housing (para 4-7c. ). Test electrical circuitry as

4-5. Tests and Inspections

follows:

NOTE

Use a multimeter and read resistance across the

Step-by-step procedures for removing and

switch terminals with the switch in the ON, mo-

replacing aiming light components are in Sec-

mentary, and OFF positions. Resistance should

tion III of this chapter.

be zero with the switch in the ON and momen-

a. Visual/Mechanical Inspection. Observe the unit

tary positions, and infinite with the switch in the

for obvious mechanical damage such as deformed

OFF position. If these readings are obtained, the

mounting bracket, inoperative switch, scratched lens,

switch asssembly circuitry is verified as con-

broken or jammed azimuth or elevation adjusters,

tinuous.

parted battery cap strap, and other evidence of damage

(2) E/ectrica/ Circuit. Reinstall the batteries (para

or misuse which might indicate a need for repair.

4-7b. ). With the switch assembly removed, short

Replace as required (para 4-7). Conduct checkout of

the switch leads together.

replacement and check proper operation of the aiming

light. If operable, return to service. If not operable,

CAUTION

continue troubleshooting.

Do not allow either lead terminal to touch the

b. Continuity Checks.

aiming light housing when batteries are in-

stalled.

(1) Switch Assembly. Remove the batteries (para

Conduct a functional test (fig. 4-l). In a d2

4-7b. ). Remove the switch assembly from the

4-1