TM 11-5855-261-23

CHAPTER

2

ORGANIZATIONAL MAINTENANCE INSTRUCTIONS

Section

I. TOOLS

AND EQUIPMENT

2-1. Tools Required

No special tools are required for organizational maintenance.

Section

MAINTENANCE CHECKS AND SERVICES

I.

2-3. Organizational Maintenance Checks

2-2. Maintenance

and Services

To ensure that the aiming light is always ready for

Organizational maintenance checks and services are

operation, organizational maintenance personnel must

outlined in table 2-1. If any part is defective or missing,

perform inspect ions to discover and correct defects

other than those parts authorized for replacement or

before they result in equipment failure. Normal

repair at organizational maintenance, refer the aiming

TAMMS procedures, TM 38-750, will be used to gather

light to direct support maintenance.

maintenance date.

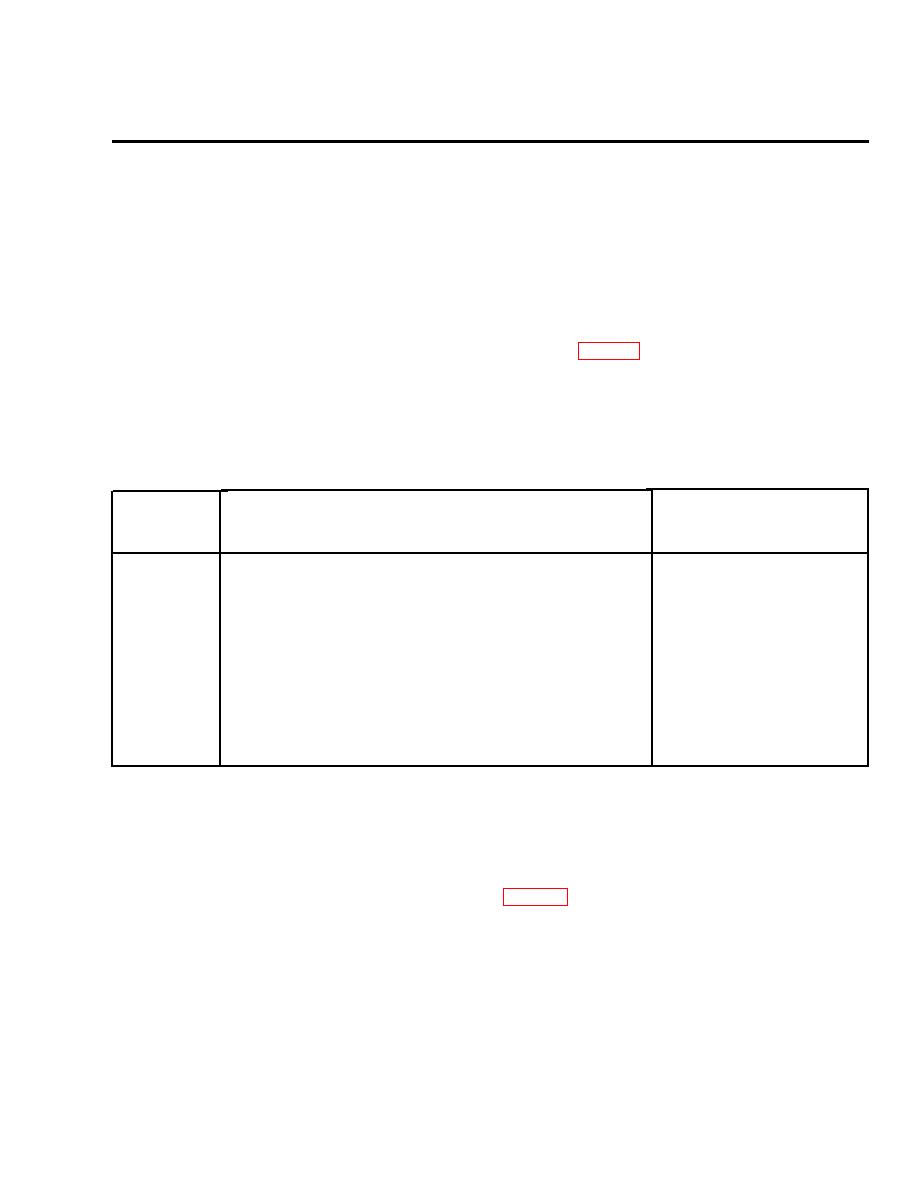

Table 2-1. Organizational Maintenance Checks and Services.

For Readiness

Reporting Equipment

Item to be Inspected Procedure

Sequence

IS Not Available if:

NO.

Aiming light is in

Visual Mechanical lnspection

1

need of repair

Observe unit for obvious mechanical damage such as deformed mounting

bracket, inoperative or broken Switch actuator, scratched lens, broken ad-

justers, , deformed battery cap, damaged battery cap gasket, parted battery

strap, or cther evidcncc of damage or misuse which might indicate a need for

repair

2

Batteries

See operator preventive maintenance checks and services (TM 11-5855-

261-10).

Cleanliness

3

Ovserve unit for cleanliness, especially dirt clogged scattershield. Clean as

required.

Section

III.

TROUBLESHOOTING

Information concerning equipment malfunctions and

2-4. Purpose of Troubleshooting

necessary corrective action which can be taken by

The purpose of troubleshooting is to identify the most

organizational maintenance personnel is contained in

frequent equipment malfunctions, their probable causes,

and corrective action required.

the operator shall be referred to organizational

maintenance.

2-5. Organizational

Troubleshooting

Procedures

2-1