TM 11-5855-261-23

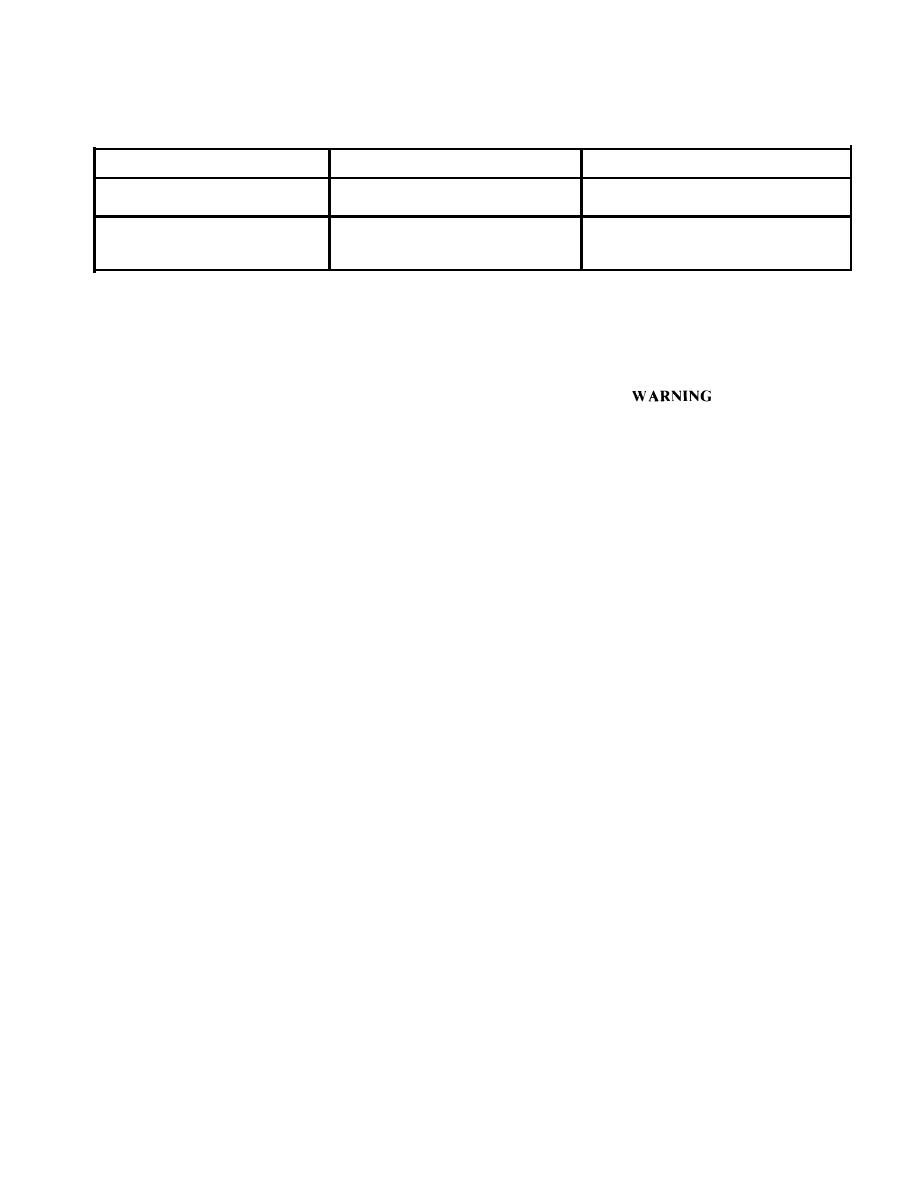

Table 2-2. Organizational Troubleshooting

Corrective Action

Probable Cause

Malfunction

Replace batteries.

Batteries dead or missing.

1. Infrared light beam fails to come on.

a. Inspect scattershield, clean as required.

a. Scattershield is plugged.

2. Infrared light appears weak.

b. Clean outside of lens with lens paper.

b. Lens is dirty on the outside.

Section IV. ORGANIZATIONAL MAINTENANCE

b. Battery Replacement. Remove the batteries from

2-6. Scope of Organizational Maintenance

the aiming light. Replace them with new batteries known

Organizational personnel are required to isolate and

to be fully charged. (See TM 11-5855-261-10 for pro-

correct malfunctions of the scattershield and batteries.

cedure.)

2-7. Check, Replacement, and Inspection

of Components

The battery contains mercury and should be

handled in the following manner:

Aiming light check, replacement, and inspection func-

1. Do not dispose in fire.

tions at the organizational level area:

2. Do not short circuit.

a. Functiona/ Check. In a dark room, turn the

3. Return batteries to Property Disposal Of-

ON/OFF switch to the ON position, (fig. 4-l). Point

ficer for disposal in accordance with DLSC

the aiming light at a wall approximately 20 meters away

Handbook 41601.

from the light. Use night vision goggles, or equivalent,

c, Scattershield Inspection. Remove the scattershield

and observe the light beam. For proper operation, a

sharp, well-defined circular spot of pulsing light should

and hold it against a light or light-colored surface.

appear. The pulsing spot should be approximately 6.5

Observe the honeycomb for evidence of dirt or other

centimeters in diameter. The aiming light must emit a

foreign substance in the honeycomb. (See TM

pulsing light beam to operate properly.

11-5855-261-10 for procedure. )

2-2