TB 1-4920-443-35

CEC 2700 oscillator pins A+ and B- from J2 connector to Pins A and B of the cable connector.

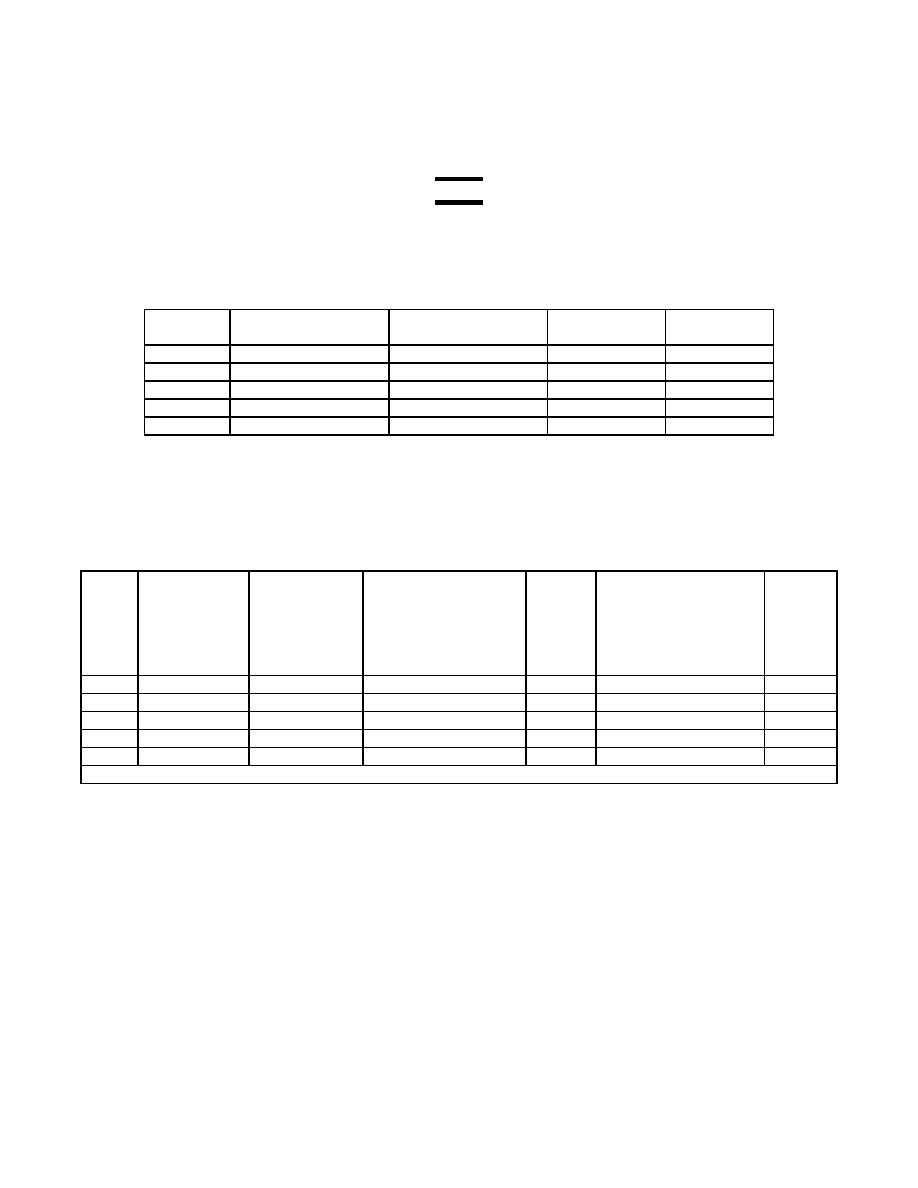

(3) Set the oscillator output to 500 mV p-p. Set the frequency to each set point shown in the table below.

(4) At each set point, record the frequency indications from the calculating counter and AEDATS. Verify

that those indications are within the tolerances specified in the table.

NOTE

To read frequency on a calculating counter channel, enter 4-10000-0 in the thumb switches.

To read frequency with AEDATS 2, refer to the AEDATS (H345-1) Operator's manual, or for

AEDATS IV, refer to the AEDATS IV (H355-7) Operator's manual.

Table 23-1 Oscillator Settings for T53/T55/T64 Fuel Flow (Frequency) Alignment

Oscillator Calculating Counter Calculating Counter AEDATS WF

AEDATS WF

(Hz)

Limits ( 1 Hz)

Reading (Hz)

Limits ( 1 Hz) Reading (Hz)

250

249-251

249-251

500

499-501

499-501

750

749-751

749-751

1000

999-1001

999-1001

1250

1249-1251

1249-1251

(5) Enter the calculated "C" factor in the Calculating Counter CH 4 C thumb switches, in the five switch

positions marked "C". Reference paragraph 23 to determine "C" factor.

(6) Verify that AEDATS Alignment was done in paragraph 24. Using the flowmeter data obtained in that

paragraph, fill-in the columns labeled "Flowmeter Hz" and "Flowmeter PPH" of the table below.

Table 23-2 Oscillator Settings for T53/T55/T64 Fuel Flow (lb/hr) Alignment

Target Flowmeter Hz

Flowmeter

Calculating Cntr.

Calc.

AEDATS WFi PPH

AEDATS

Freq. from table 21-

PPH

Limits

Counter

Limits

WFi

(Hz)

1

from table 21-

(calculated as

Reading

(calculated as

Reading

1

follows)

follows)

Flowmeter PPH

Flowmeter PPH

0.5%

0.35%

250

500

750

1000

1250

Note: Calculating Counter Reading = Oscillator Frequency x C, where C is calculated in paragraph 21.

(7) Connect the thermocouple calibrator to the fuel temperature thermocouple connector (TC208) Pins A

(+) and B (-). Set the output for Type J output at a temperature that corresponds to calibration

temperature from the flowmeter calibration sheet.

(8) Set the oscillator output to 500 mV p-p. Set the frequency to each of the set points in the "Flowmeter

Hz" column of the table above. Record the fuel flow indications from the calculating counter and

AEDATS and verify that those indications are within the specified tolerances.

(9) Reconnect the fuel flowmeter cable and fuel thermocouple.

(10)The turbine flowmeter should be calibrated by a qualified laboratory every twelve (12) months.