TM 9-1290-357-15

(6) To prevent excessive damage and wear

d. Preventive Maintenance Checks and Serv-

of threads, never tighten leveling screws, clamp-

ing screws, etc., beyond a snug fit or their capa-

maintenance checks and services which will be

ble limits. The azimuth worm shoe throwout de-

performed at the designated intervals; however,

vice should be used carefully to avoid damaging

these services will also apply to organizational,

the worm.

(7) Any instrument which cannot be ad-

direct support, general support, and depot main-

justed or corrected by the authorized procedure

tenance personnel who may have the occasion to

must be brought to the attention of responsible

use, stow, package or ship the equipment.

personnel.

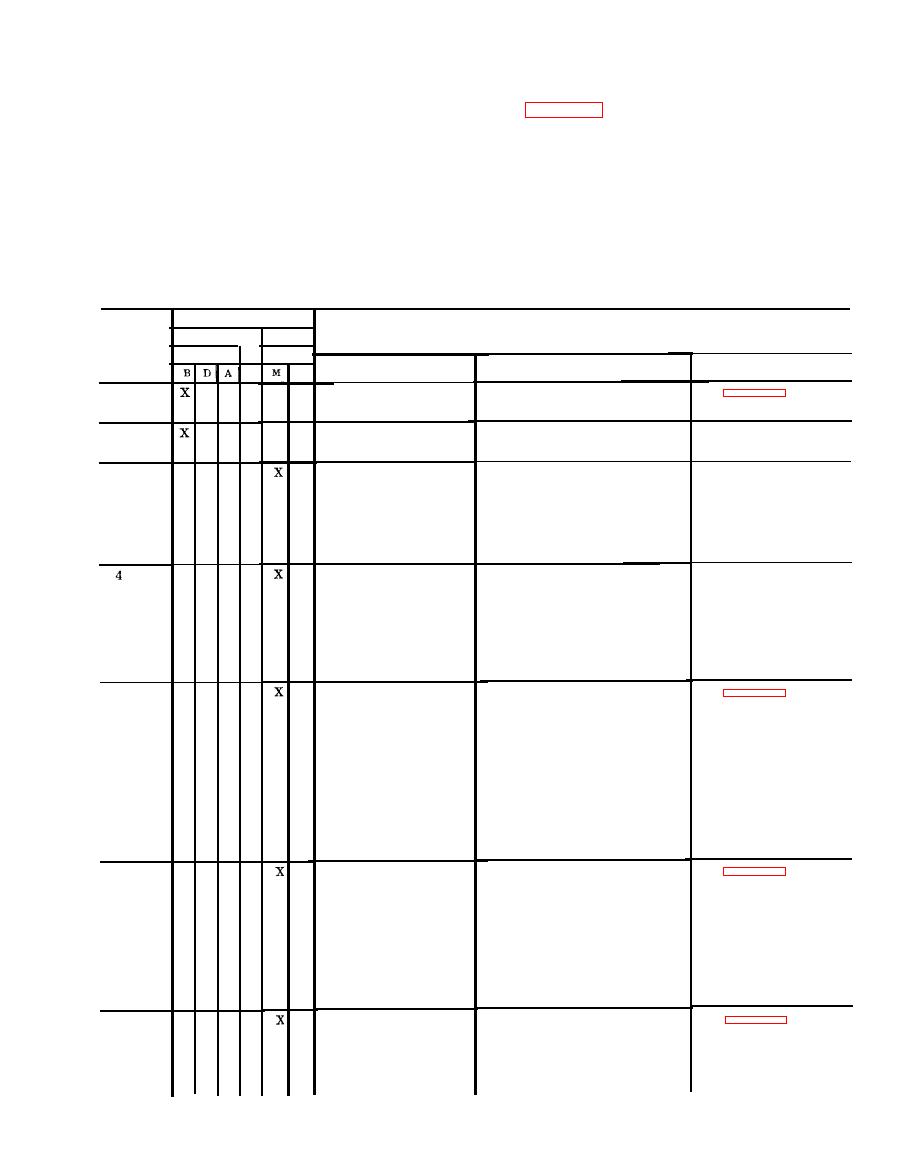

Internal

M--Monthly

A--After Operation

B--Before Operation

Q--Quarterly

W--Weekly

D--During Operation

Org

Operator

Item

no.

Daily

Reference

Procedure

Item to be

W

inspected

Q

Clean

and

wipe

dry.

1

Aiming

circle

M1,

X

exterior

surface.

Tighten

external

screws

or

nuts.

X

Exposed

mechanical

2

Report

missing

parts.

components.

Traverse

instrument

6400

mils

Azimuth

and

orienting

mechanisms.

in

azimuth

using

orienting

and

azimuth

knobs. Note.

If

there

is

any

binding

or

stick-

ing,

disassembly

and

repair

will

be

required.

Elevate

and

depress

telescope.

Elevation

Note.

If

there

is

any

binding

mechanism.

in

mechanism

as

knob

is

ro-

tated,

or

if

pressure

is

not

exerted

by

the

compression

spring,

disassembly

and

re-

pair

will

be

required.

Point

optics

skyward

or

at

a

Optics.

5

bright

light,

looking

through

the

objective

end

for

dirt,

smears,

fungus

growth,

scratches,

digs,

chips,

or

cement

separations.

Note.

If

defects

are

sufficient

to

interfere

with

the

use

of

the

instru-

ment,

disassembly

and

repair

will

be

required.

Check

accuracy

by

rotating

the

Circular

6

leveled

instrument

slowly

level

vial.

through

a

full

turning

azi-

muth.

The

bubble

should

remain

centered

at

any

position

in

azimuth. Note.

If

bubble

does

not

remain

cent-

ered,

level

vial

should

be

replaced.

Check

simultaneous

readings

of

Azimuth

scale

and

7

scale

and

micrometer

zeros.

Note.

If

does

not

indicate

zero

when

scales

do,

loosen

clamping

screws

or