TM 9-1290-357-15

Section IV. TROUBLESHOOTING

3-12. Procedure

3-11. Scope

The troubleshooting procedure described in table

Troubleshooting is a systematic isolation and re-

m e d y of malfunctions and defective components

bable causes, and the necessary corrective action

b y means of symptoms and tests. The tests and

r e q u i r e d to remedy the malfunction. Corrective

remedies provided in this section are to be per-

a c t i o n that is beyond the scope of the operator

formed by the operator, organizational and direct

w i l l be taken by the organizational, direct sup-

s u p p o r t maintenance personnel. Tests and reme-

p o r t , general support or depot maintenance per-

dies not listed in this section are to be performed

sonnel.

b y general support and depot maintenance per-

sonnel.

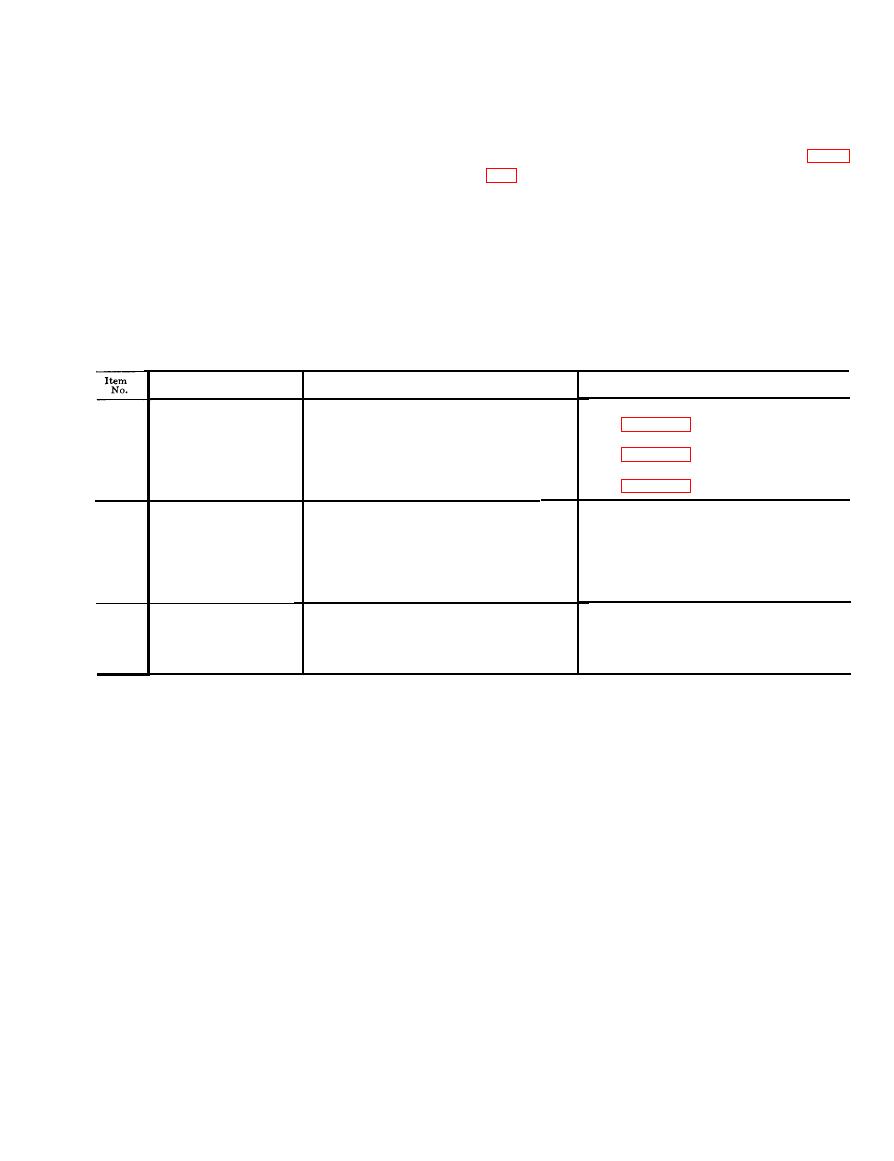

Table 3-2. Troubleshooting

Corrective

action

Malfunction

Probable

cause

a. Lamp burned out.

a. Replace lamp.

1

Failure to

illuminate.

b. Replace battery.

b. Defective battery.

c. Replace switch.

c. Defective switch.

a. Clean with lens

a. Dirt, dust, or fingerprints on

2

Poor vision.

paper tissue.

windows or eyepiece optics.

b. Allow instrument to reach

b. Condensation on entrance

ambient temperature.

window or eyepiece optics.

c. Notify direct support

c. Damage or broken window

maintenance personnel.

or optics.

a. Notify direct support

a. Binding and/or a rough motion

3

Controls not

personnel.

functioning

when operating controls.

properly.

b. Defective or broken

components.

Section V. REPAIR OF AIMING CIRCLE M1

(a) To remove dust, dirt, lint and any

General

f o r e i g n matter from surface brush lightly with

This section contains general and specific or-

a clean camel's hair artist brush then tap handle

g a n i z a t i o n a l maintenance instructions for the re-

against a hard surface to knock out small parti-

p a i r of the major item. Specific repairs and in-

c l e s which may have clung to the hairs of the

s p e c t i o n s within the scope of the organizational

brush. Repeat this frequently.

l e v e l of maintenance are described in order to

Caution: Under no circumstances use polish-

restore the major item to a serviceable condition.

ing liquids, pastes, or abrasives when cleaning

plastic, glass, or optical surfaces.

3-14. Maintenance

(b) After surface has been cleaned wipe

a. Cleaning.

surface with a lens paper tissue.

(1) Metal parts. Use dry cleaning solvent or

(c) Moisture due to condensation may col-

volatile mineral spirits (and a clean soft lint-free

l e c t on the optical surfaces when the tempera-

c l o t h ) to clean metal parts in accordance with

t u r e is lower than that of the atmosphere. This

instruction in TM 9247.

m o i s t u r e , if not excessive, can be removed by

(2) Rubber or plastic parts. C l e a n r u b b e r

placing the instrument in a warm place.

and plastic parts with soap and warm water.

Cauton: Do not place the instrument directly

(3) Optical surfaces.

3-5