TM 9-1290-357-15

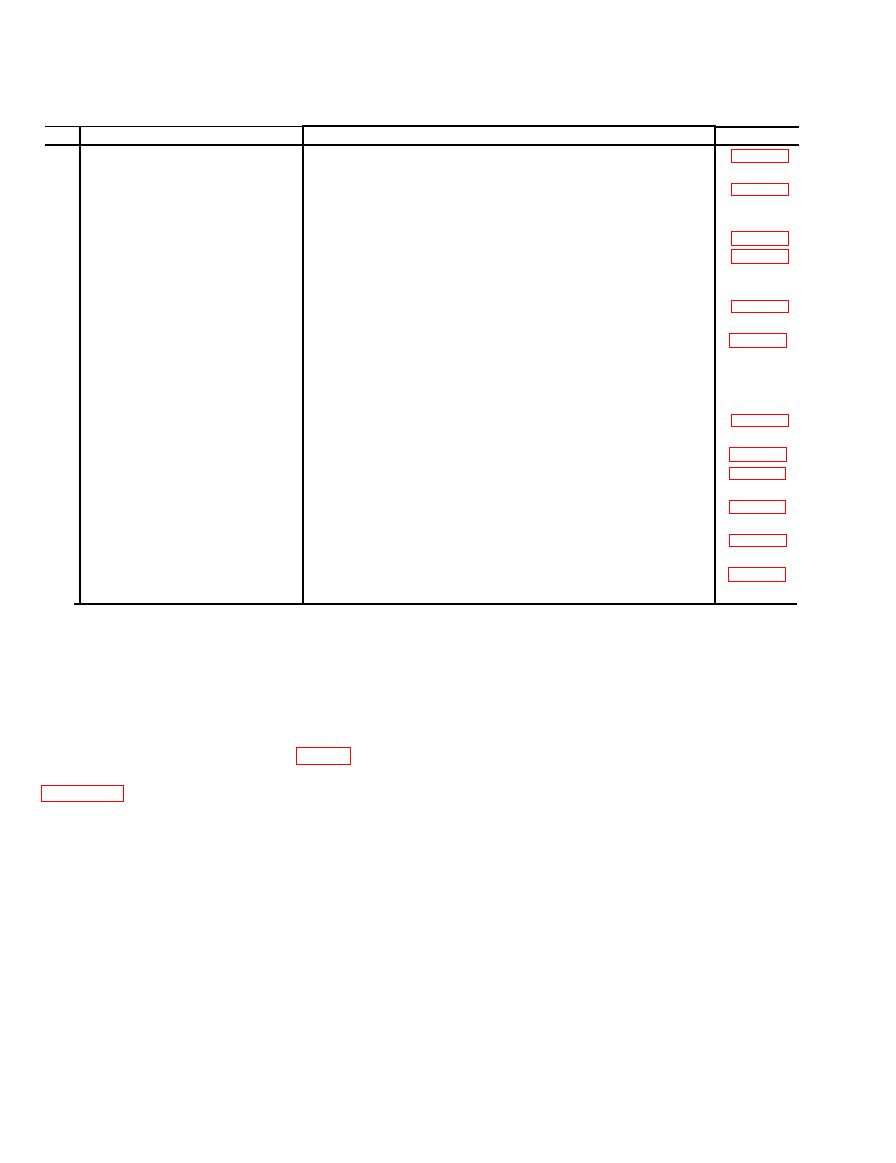

Item

Designation

Function

Reference

1

Eyepiece focusing

Focuses clear definition of the reticle pattern

and field of view.

sleeve.

2

Permits telescope assembly to rotate vertical-

Elevation knob.

ly, approximately 8 (142 mils) above or

below the horizontal.

3

Telescope level vial.

Indicates when telescope is level horizontally.

4

Azimuth worm knob

Rotates the telescope assembly and azimuth

and micrometer.

scale index 360 (6400 mils) for fine

adjustments.

5

Circular level assembly.

Indicates when azimuth circle is in a horizont-

al plane.

Azimuth worm shoe

6

Disengages the azimuth worm gear allowing

(throw-out device).

rapid approximate settings in azimuth.

Coarse adjustment for measuring azimuth.

Fine adjustment when azimuth mechanism

is engaged.

7

Orienting knob.

Rotates the aiming circle (with the exception

of the orienting worm housing) in azimuth.

8

Clamping screw.

Clamps equipment securely.

9

Magnetic needle.

Permits orienting with magnetic north as

reference.

10

Magnetic needle

Magnifies the etched line on south end of

magnifier assy.

needle.

11

RED locking plunger

Locks the magnetic needle.

button.

12

Releases the magnetic needle.

OLIVE releasing

plunger button.

Section Ill. OPERATION UNDER USUAL CONDITIONS

b. Stops are provided on instrument to limit

General

the travel of moving parts.

This section contains instructions for the proper

care of the materiel, preparation for use, and op-

Caution: Do not attempt to force the rotation

eration of aiming circle M1, w/e (fig. 11). For

of any knob beyond the stop limit which may

operation under unusual conditions refer to para-

damage components or cause malfunctioning of

the instrument.

c. Keep instrument dry as possible. If wet, dry

2-7. Care in Handling

it thoroughly using a clean lint free cloth be-

fore storing.

Aiming circle M1, w/e is, in general, rugged and

suited for the purpose for which it was designed,

Note. Wipe optical elements with lens paper tissue only.

however, it will not stand rough handling or a-

d. When not in use, keep the instrument cov-

buse. Inaccuracy or breakage will result from

ered and protected from dirt, dust, moisture, chip-

mistreatment. Any instrument that is function-

ping, scratching and destruction using the pro-

ing inaccurately or contains damaged parts must

vided carrying case M6A1.

be brought to the attention of the organizational

maintenance personnel for disposition. Repair

e. Do not point instrument directly at the sun,

other than those expressly authorized will not be

as the heat of the focused rays may damage the

performed by the operator.

optical elements and the eyes.

a. Unnecessary turning of screws or other part

f. Keep all exposed surfaces clean and dry pre-

not incident to the use of the instrument is for-

venting corrosion, accumulation of dirt of any

bidden.

foreign matter, or etching of optical elements.

2-2