TM 9-1290-357-15

Internal

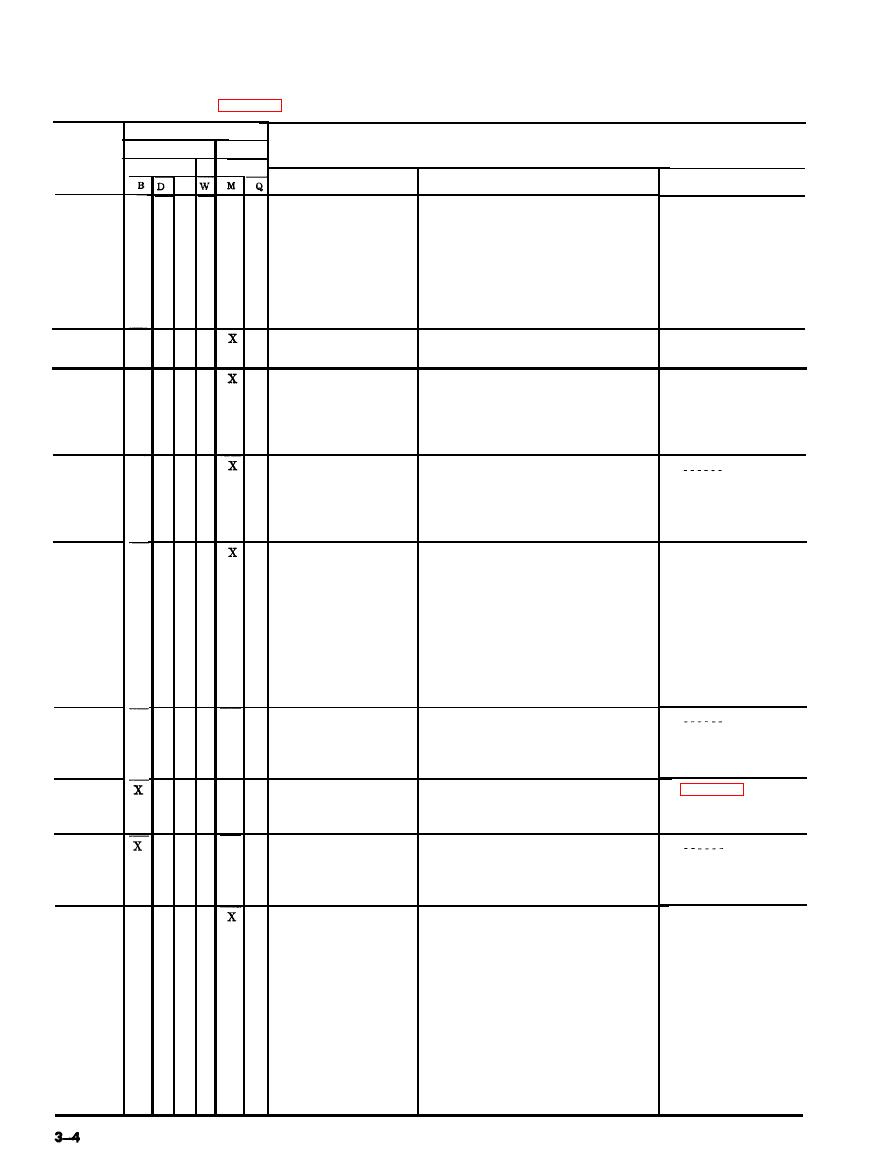

B--Before Operation

A--After Operation

M--Monthly

D--During Operation

Operator

Org

W--Weekly

Q--Quarterly

Item

no.

Daily

Item to be

Procedure

Reference

A

inspected

nuts on micrometer knob and

while holding the knob to

prevent the scale from mov-

ing off its index, slip microm-

eter to read zero. Tighten

clampoing screws or nut.

Check zero reading with scale

again repeat if necessary.

8

Magnetic needle

------

Inspect for scratches, dirt,

reticle.

and chips.

9

------

Place instrument on a level

Magnetic needle

balance.

surface away from iron or

steel objects. Both ends cf

the needle should be the same

distance away from the glass.

10

Magnetic needle

Place instrument on a level

polarity.

surface away from iron or

steel objects. The north seek-

ing end of the needle should

point to the north.

11

Magnetic needle

Place instrument on a level

------

pivot.

surface. Displace needle by

passing an iron or steel ob-

ject across the path of the

needle. If needle does not

swing freely and come to

rest on the same reference

line in 4 seconds notify

direct support maintenance

personnel.

12

Clean exterior and interior

Carrying case.

X

periodically by brushing or

compressed air to remove

any foreign matter.

13

Instrument light M2.

Check for proper illumination,

lamps, switch, and battery

and replace if necessary.

14

Clean. Oil ball and socket joint.

Tripod, ball

X

Note. Do not disassemble the

and joint.

joint. Use only lubricating

type oil.

-----

15

Tripod.

Check legs and support for

bends, nicks and dents. Cent-

er sections should move free-

ly up and down and should

clamp rigidly in any desired

position when released.

Sufficient friction should be

present to allow adjustment

of aiming circle without

falling. Note. Dissembly or

repair will be required if any

of the above conditions are

not satisfied.