TM 5-6675-318-14

(c) Securely crimp the cable terminal and cut off the excess.

(d) Remove all tape from motor and pulleys.

(e) Remove nuts from pen holder assembly.

(f) Reinstall trailing cable termination bracket over threaded

Reinstall nuts and tighten.

studs.

(g) Position pen solenoid wires so that they will not rub on

pulleys.

(h) Reinstall trailing cable tray cover. Check ends for flush

fit.

CAUTION

D o not touch dashpot piston with bare hands. Skin oils will damage surface

of piston.

( i ) R e i n s t a l l d a s h p o t a s s e m b l y . H o o k end of piston into notch and

position spring over pin. If piston becomes separated from

dashpot, do not touch with bare hands.

(j) Position upper pen holder and install screw.

(k) Reinstall pen holder cover and install screw.

(l)

Position

plotter

arm

at

the

left

(pen

stall)

end

of

plotter.

(m) Position pen carriage assembly at top right corner of platen.

(n) Pull on loose cable at loop crimp terminal until all slack is

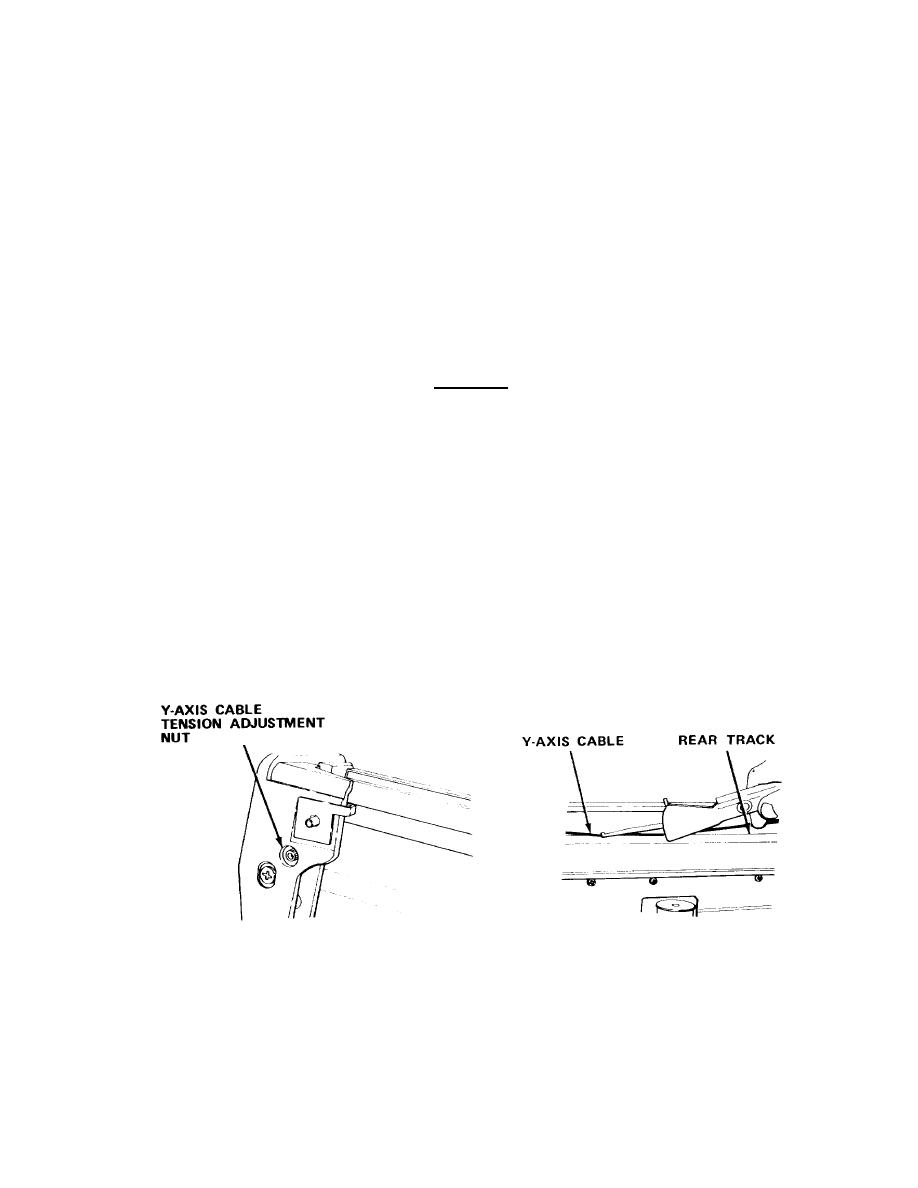

L o c a t e midpoint between two pulleys on Y-

gone from cable.

axis cable.

3-305