TM 5-6675-317-14

5-14. ORGANIZATIONAL PREVENTIVE MAINTENANCE CHECKS AND SERVICES.

There are no organizational PMCS procedures assigned for this equipment.

5-15. ORGANIZATIONAL TROUBLESHOOTING PROCEDURES.

a. Organizational troubleshooting procedures cover the most common malfunctions

that may be repaired at the organizational level.

Repair or adjustment requiring

specialized equipment is not authorized unless such equipment is available. Trouble-

shooting procedures used by the operator should be conducted in addition to the

organizational troubleshooting procedures.

b.

This manual cannot list all the possible malfunctions or every possible test/

inspection and corrective action.

If a malfunction is not listed or corrected by a

listed corrective action, notify your supervisor.

c.

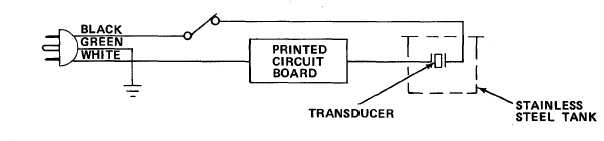

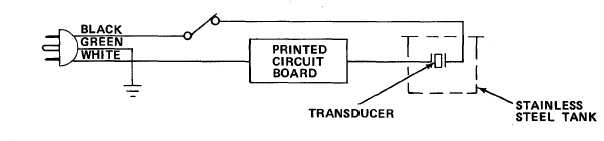

For unidentified malfunctions, use the facing schematic or the foldout located

at the end of this manual for further fault analysis.

d.

If the ultrasonic cleaner does not power up when turned on, verify that 120 V

ac is present at the receptacle.

If voltage is not present, plug equipment into

receptacle with power available and proceed with equipment troubleshooting.

Perform

no-power procedure for dead receptacle (Table 1-4).

Table 5-2. ORGANIZATIONAL TROUBLESHOOTING

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1.

NO CLEANING ACTION, WATER AGITATES.

Check cleaning action using fresh cleaning solution.

(a) If test was satisfactory, instruct operator to change cleaning

solution when dirty.

(b) If test was not satisfactory, replace circuit board (paragraph

5-16.3).

5-9