TM 5-3610-286-10

2-7.

OPERATING PROCEDURES (CONT)

d.

Prepare Dampening Assembly (Cont)

(a) Remove cylinder guard.

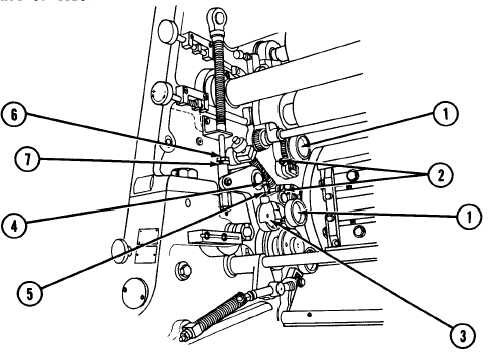

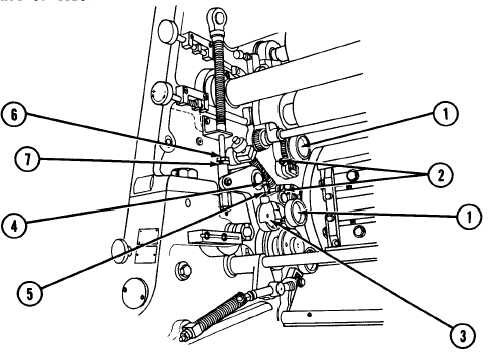

Using T-handle wrench (1). disengage

dampening form

knob to left.

roller journals from plate cylinder by turning disengaging

(b) Insert dampening form roller no. 21 with ball bearings mounted

on spindles into roller journal (1) on operator side first.

Then, insert

into journal on drive side.

NOTE

Rollers are adjusted properly when 0.004 in. (0.10

mm) feeler gage moves between dampening form rollers

no. 20 and no. 21 and dampening oscillator roller no.

22 with light resistance.

(c) Using T-handle wrench , engage rollers to plate cylinder.

(d) Move dampening form roller control lever to left (off)

position.

(e) Using pin wrench and 0.10 mm feeler gage, adjust dampening form

rollers no. 20 and no. 21 to dampening oscillator roller no. 22 using worm

screws (2) at operator and drive sides of Printing Press.

Turn worm screws

(2) left to decrease pressure and right to increase pressure.

2-67