TB 1-4920-443-35

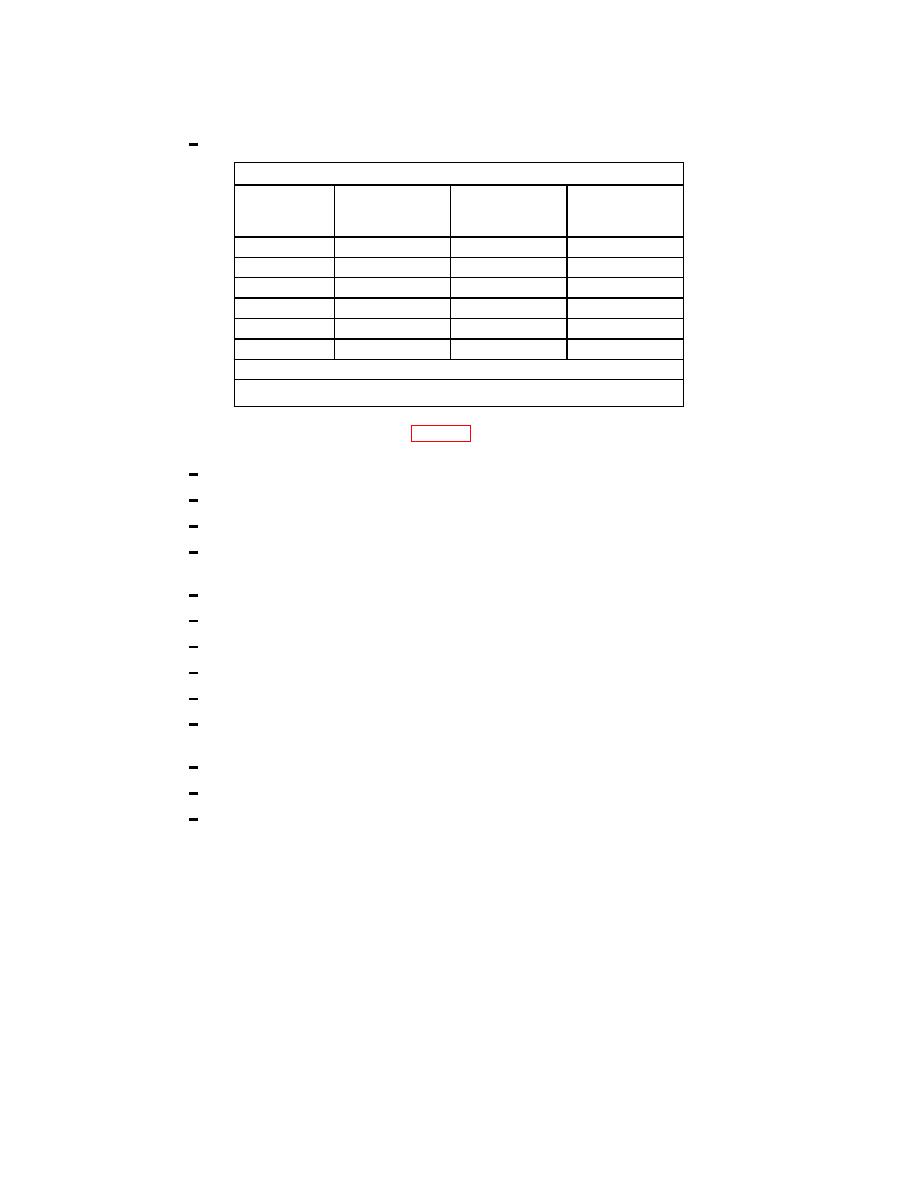

AEDATS IV T64 ALIGNMENT WORKSHEET

(g) MT-13 0-50 psig Dyno Inlet Pressure

1 Using the pressure calibrator, apply the following pressures to MT-4, and record the results.

Vertical Scale bottom row 11

5SE01313-4

Actual

AEDATS 4

6SE00950-2

Pressure

Pressure

(Pdyn_sup)

Vertical Scale

(psig)

psi

+/- 1 psi

+/- 2 psi

Vent

____________

____________ ____________

10

____________

____________ ____________

20

____________

____________ ____________

30

____________

____________ ____________

40

____________

____________ ____________

50

____________

____________ ____________

R-cal

____________

Transducer: T34 Hardware Name: HL13

(10)T-64 Fault light panel

(Refer to page 75 step 58)

(a) J BOX

1 Dyno low oil pressure fwd ______17PS Set at 10.5 psig on decreasing pressure +/-.5

Fuel pressure

_______18PS Set at 8 psig on decreasing pressure +/-1

2

Low oil pressure Eng T53

_______15PS Set at 25 on decreasing pressure +/-1

3

Dyno low oil pressure aft

_______16PS Set at 10.5 psig on decreasing pressure+/-.5

4

(b) T64 Test Trailer

1 Chip detector

_______Touch chip detector lead to ground

Dyno supply low pressure

_______19PS on trailer set at 10 psig on DEC. press +/-1

2

Dynolube filter delta-p

_______18PS on trailer set at 10 psig on INC. press +/-1

3

Dynolube tank low level

_______Jumper pins F & G at J103 aux. J-box

4

T64 oil Filter delta-P

_______10PS Low side Vented High side 8 psi +/-1

5

T64 Low Oil Level Engine

_______Jumper pin at float switch at tank

6

(c) Fuel Skid

1 Fuel boost pressure

_______ 2 PS set 15 psi on increasing pressure +/-1

Main Fuel valve closed

_______Turn on CB305 Press fuel pump switch on

2

Fuel valve select

_______Turn on CB305 and fuel pump switch

3

205