TB 1-4920-443-35

AEDATS IV T700 ALIGNMENT WORKSHEET

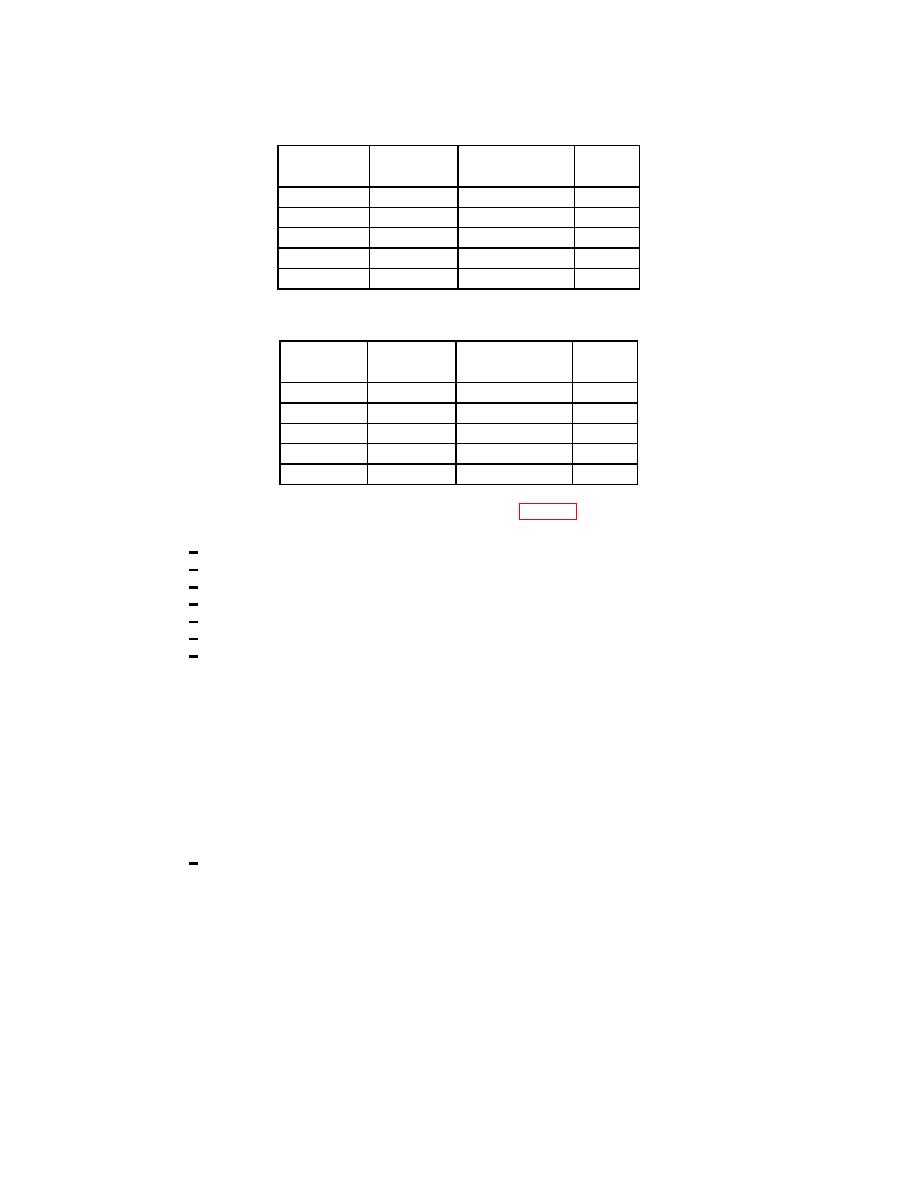

(e) Channel 2 Connector J38 (V2) (charge amp box)

Frequency

Output

(Vert. Scale)

(Limits)

(Pcmb/mv)

Meter

100hz

81.4

____________

.9-1.1

100hz

163

____________

1.9-2.1

100hz

244

____________

2.9-3.1

100hz

326

____________

3.9-4.1

100hz

407

____________

4.9-5.1

(f) Channel 3 Connector J37 (V3) (charge amp box)

Frequency

Output

(Vert. Scale)

(Limits)

(Pcmb/mv)

Meter

100hz

16.3

____________

.9-1.1

100hz

32.5

____________

1.9-2.1

100hz

48.8

____________

2.9-3.1

100hz

65.1

____________

3.9-4.1

100hz

81.4

____________

4.9-5.1

(a) Set calculating counter controls as follows: (Channel 4)

1 DEC

6

2C

01000

3 10n

0

4 Auto

depressed

5 X10

depressed

6 Sample Rate (fast)

1

7 Test

released

(b) Determine C settings for channel 4 Channel 4 C = (3600 x 8.337 x specific gravity) divided by the

turbine meter K-factor ( Average from calibration sheet)

(c) Enter calculated value on channel 4 C switches

(d) At the fuel trailer disconnect MT-206 from the flowmeter and connect the test oscillator to pins A

(+) and B (-).

(g) Enter Specific Gravity, K Factor and Temp in AEDATS to read PPH from flowmeter Cal sheet.

(h) Connect Temp source to TC 208 to correspond to flowmeter Cal Temp.

1 1 Vac input

(Note: oscillator frequency x c = PPH)

(Enter S/G into AEDATS to read PPH from Cal sheet)

166