TB 1-4920-443-35

AEDATS II T53 ALIGNMENT WORKSHEET

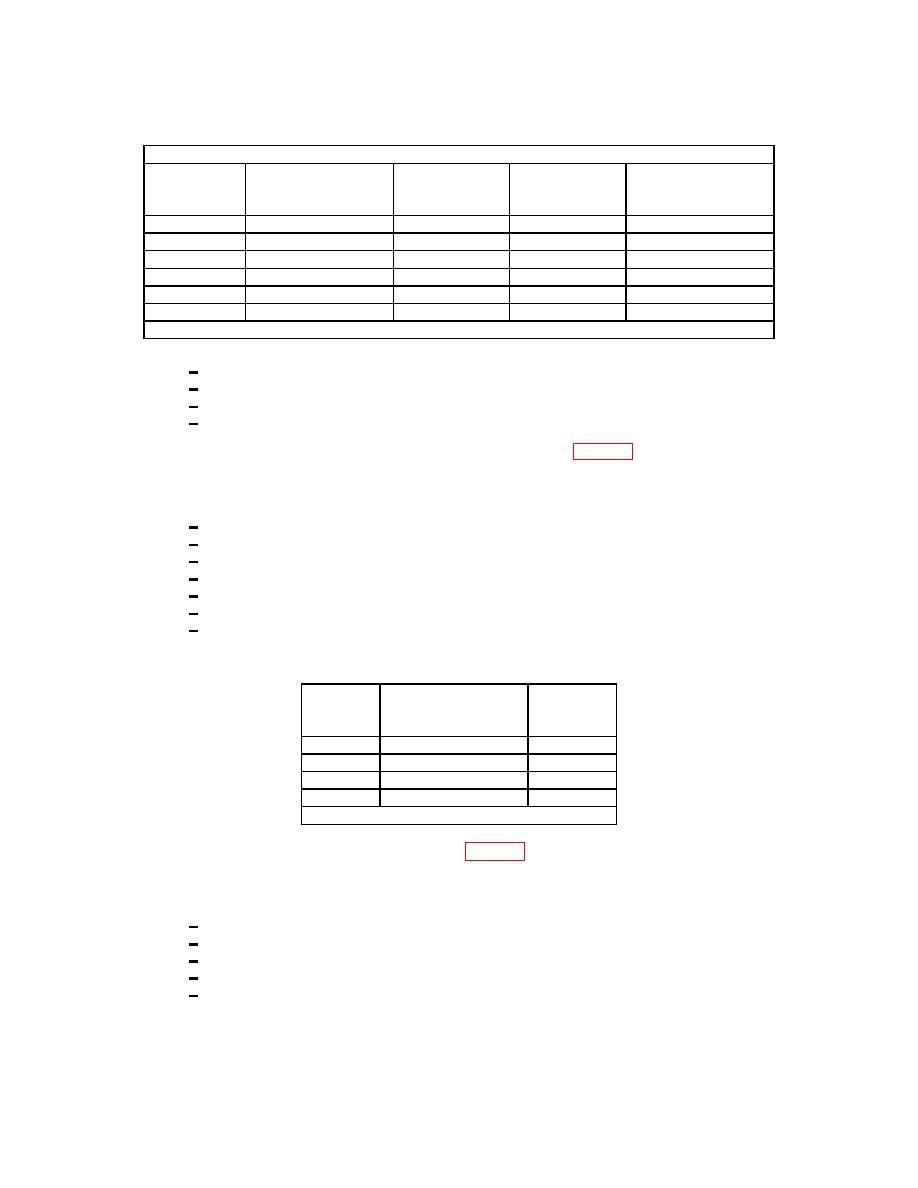

(l) Input the following frequencies into TB 201 pins 1 (+) and 2 (-).

Note: Cell constant Low K Factor (#3)

Oscillator Hz

Calculating Counter

AEDATS 2

Calculating Counter

+/- 1 Hz

Sheet Hz

PPH+/- .35 %

(WF1)

+/- 1 Hz

0Hz

____________

____________ ____________

____________

600Hz

____________

____________ ____________

____________

800Hz

____________

____________ ____________

____________

1000Hz

____________

____________ ____________

____________

1200Hz

____________

____________ ____________

____________

1400Hz

____________

____________ ____________

____________

(Note: frequency x C = PPH) (CH 4C= 3600 x 8.337 x SG /K factor)

K- Factor = Hz. x Time base / Flow rate

1

PPH= GPM x 500 x SG. Or GPM= PPH/500xS.G.

2

PPH= Pulses per second (Hz). x 3600 x S. G. x 8.347 / pulses per gallon ( K Factor)

3

Correction Factor 78 x 8.337 x SG / 2000

4

(10)Oil flow measurement CEC 2700 BOX T53/T63

(Refer to page 20 step 24)

(a) Ensure the system is in the T53/T63 test mode, with the correct flight harness connected to the J-

box.

(b) Set calculating counter controls as follows: (Channel 3)

1 DEC

6

2 C

01000

3 10n

0

4 Auto

depressed

5 X10

depressed

6 Sample Rate (fast)

1

7 Test

released

(c) At the Large Engine Test Trailer, disconnect the cable from the T53/T63 Oil Flowmeter. Connect

the CEC 2700 oscillator to pins A and B of the cable connector.

Oscillator

Calculating Counter

AEDATS 2

(Hz)

+/-1 Hz

(WF2)

(Hz)

300

600

900

1300

Note: frequency x C = PPH

(11)Vibration system, T-53/55/63

(Refer to page 14 step 18)

(a) Set variable filter channel switches to 2, on channels 1, 2 and 3 filter selector switch to out, and

power switch to on.

(b) Set all meters as follows:

1 Filter switch to

CAL

2 Range switch to

150

3 Xducer to

ACC

4 Mode switch to

ACC

5 Output switch to

AVG

(c) Adjust cal pot to 105 on digital display on all channels

(d) Set filter switch to sensitivity and adjust sens pot for an indication of 150 on all channels

126