TM

9-4931-436-14&P

CHAPTER 4

ORGANIZATIONAL

MAINTENANCE

INSTRUCTIONS

SERVICE UPON RECEIPT OF MATERIAL

Section I.

4-l. INSPECTION, SERVICE, INSTALLATION,

AND SETUP INSTRUCTIONS. Refer to

PARTS, SPECIAL TOOLS, AND EQUIPMENT

Section II.

4-2. PARTS, SPECIAL TOOLS AND EQUIP-

special tools list (RPSTL), appendix C.

MENT. Tools and repair parts, including

No special tools are required for align-

bulk material s, required for organiza-

device organizational maintenance.

ment

tional maintenance are contained in the

maintenance allocation chart (MAC),

PREVENTIVE MAINTENANCE CHECKS AND SERVICES

Section III.

maintenance for inspection and correc-

4-3. ORGANIZATIONAL PREVENTIVE MAIN-

TENANCE. Preventive maintenance is

tion as authorized.

necessary to ensure that MILES equip-

4-4, ORGANIZATIONAL PREVENTIVE MAIN-

ment is always ready for operation.

TENANCE CHECKS AND SERVICES. Organiza-

Organizational maintenance personnel

tional (before, during, and after

must perform a systematic inspection

operation) preventive maintenance checks

to discover and correct defects before

and services are outlined in table 4-l.

they result in operational failure of

the equipment. Defects or malfunctions

If any part is defective or missing,

other than those parts authorized for

discovered by the operator during use,

or as a result of performing daily

replacement or repair at organizational

maintenance, refer the equipment to the

maintenance checks and services,

next higher level of maintenance.

will be reported to organizational

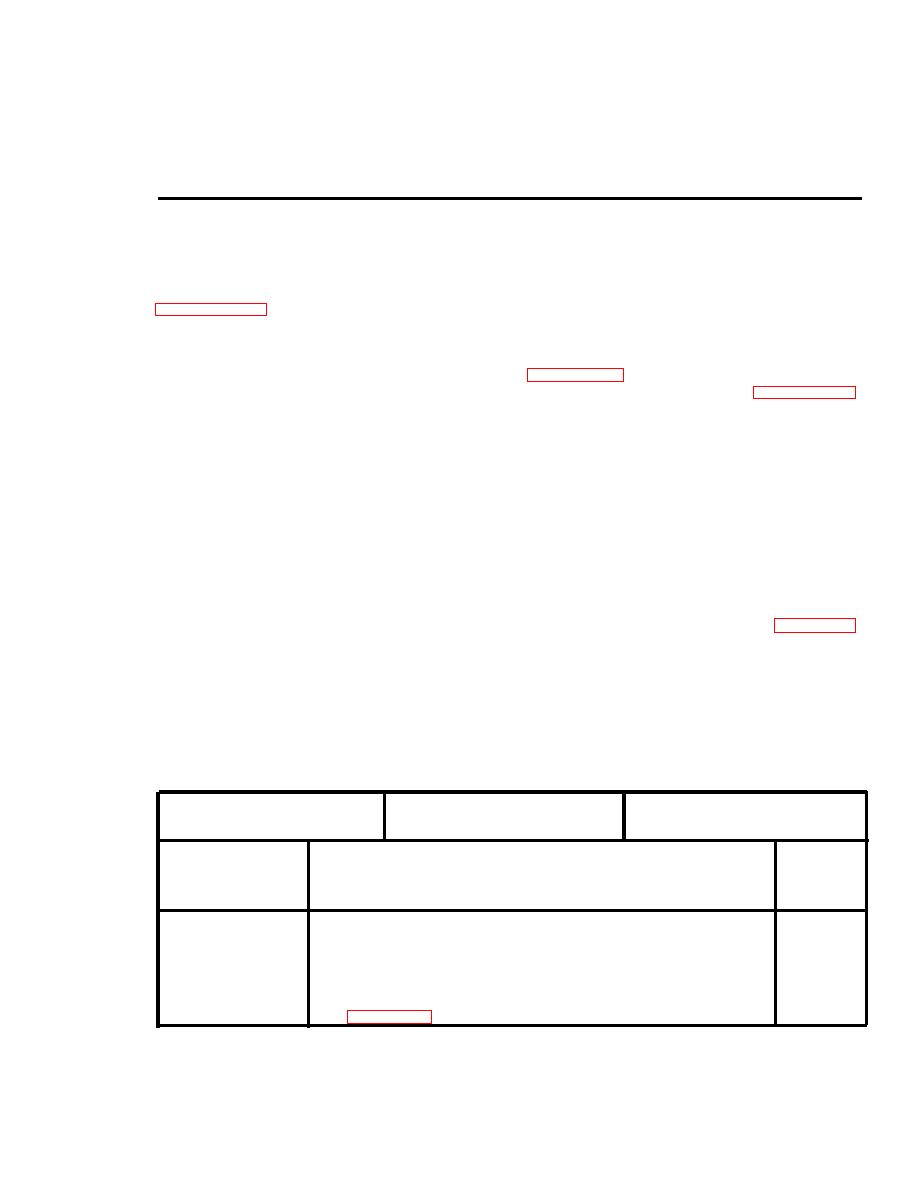

Table 4-l.

Organizational Preventive Maintenance Checks and

Services, Alignment Device

A - After Operation

B - Before Operation

D - During Operation

Time Required:

Time Required:

Time Required:

Work

Interval and

ITEM TO BE INSPECTED

Time

Sequence No.

PROCEDURE

B

D

A

(M/H)

NOTE

Organizational preventive maintenance checks and

services are the same as at operator/crew main-

tenance level as of the publication date, refer

to table 3-l.

4-1