TM

9-4931-436-14&P

CHAPTER 3

OPERATOR/CREW

MAINTENANCE

INSTRUCTIONS

PREVENTIVE MAINTENANCE CHECKS AND SERVICES

Section I.

3-1. OPERATOR/CREW PREVENTIVE MAINTE-

organizational maintenance for inspec-

The purpose of preventive

NANCE.

tion and correction.

maintenance is to ensure that the

device

is always ready for

alignment

Operator/crew preventive maintenance

operation. The operator must perform

checks and services are outlined in

a systematic inspection to discover

defects before they result in opera-

operating the alignment device are num-

Defects

bered sequentially and appear in the "B"

tional failure of eqiupment,

column under the heading Interval and

or malfunctions discovered by the

Sequence No. The work-time for each

operator during use, or as a result

task is given in manhours, to one decimal

of performing daily maintenance checks

place, in the work time (M/H) column.

and services, will be reported to

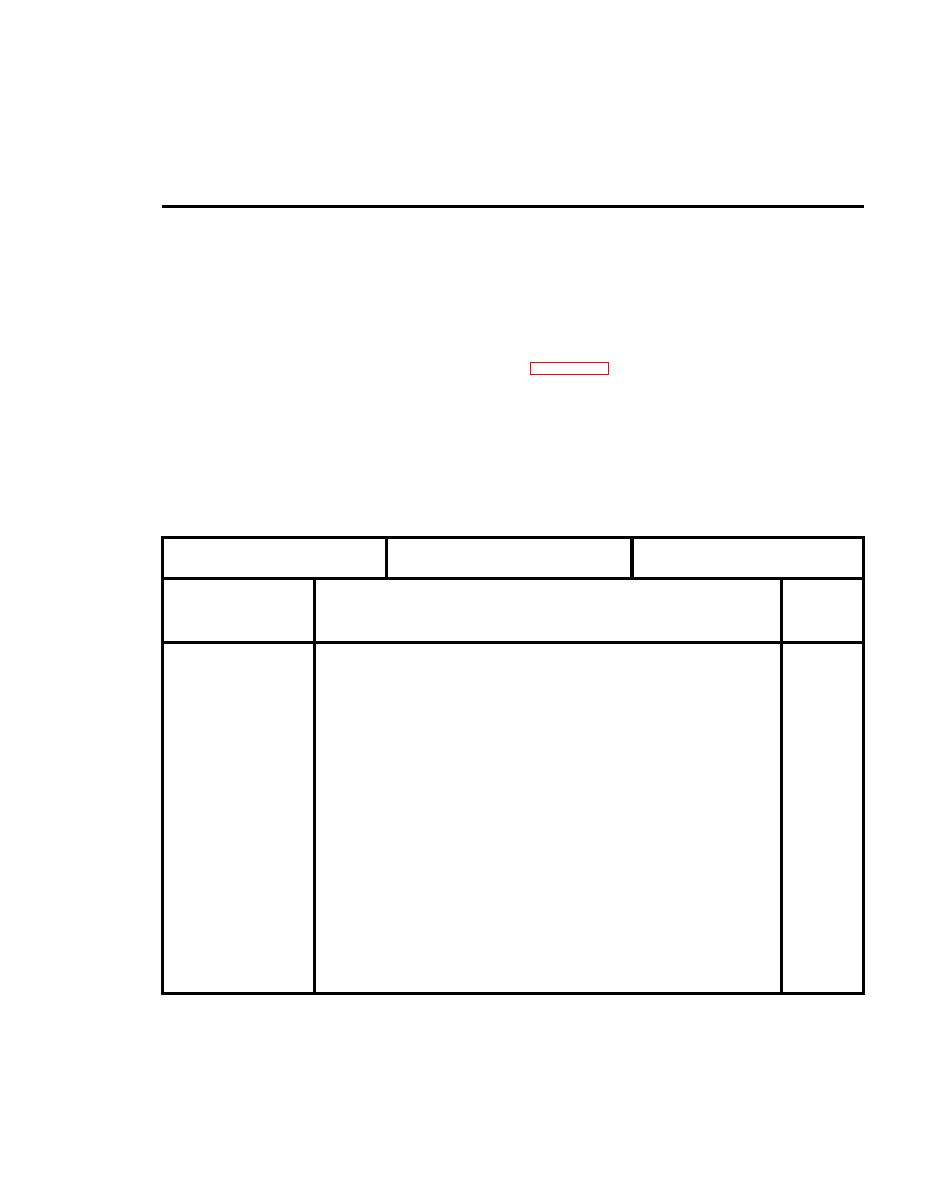

Table 3-1.

Operator/Crew Preventive Maintenance Checks and Services

A - After Operation

D - During Operation

B - Before Operation

Time Required: 0.8

Time Required:

Time Required: 0.8

Work

Interval and

ITEM TO BE INSPECTED

Time

Sequence No.

PROCEDURE

B

D

A

(M/H)

0.1

INSTRUMENT CASE - Visually inspect for damaged

9

1

latches, case damage, and dirt. Report to higher

level maintenance if damaged.

0.1

BUILT-IN VOLTAGE METER - Visually inspect to ensure

10

2

face covering is undamaged. Report to higher level

of maintenance if damaged.

0.1

25-METER LINE - Visually inspect to ensure that

11

3

line is unknotted and intact. Replace if damaged.

0.1

BATTERY CHECK Pushbutton Switch - Visually inspect

12

4

to ensure switch is undamaged. Press to ensure

free action. Report to higher level maintenance

if damaged.

0.1

POWER ON Pushbutton Switch - Visually inspect to

13

5

ensure switch is undamaged. Press to ensure free

action. Report to higher level maintenance if

damaged.

3-l