TM 5-6675-328-14

4-15. ORGANIZATIONAL TROUBLESHOOTING PROCEDURES.

a.

Organizational troubleshooting procedures cover the most common malfunctions that may be repaired at the

organizational level. Repair or adjustment requiring specialized equipment is not authorized unless such equipment is

available. Troubleshooting procedures used by the operator should be conducted in addition to the organizational

troubleshooting procedures.

b.

This manual cannot list all the possible malfunctions or every possible test/inspection and corrective action. If a

malfunction is not listed or corrected by a listed corrective action, notify your supervisor.

c.

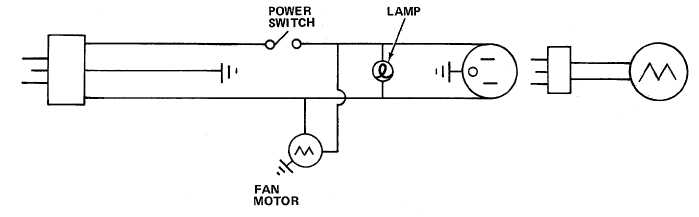

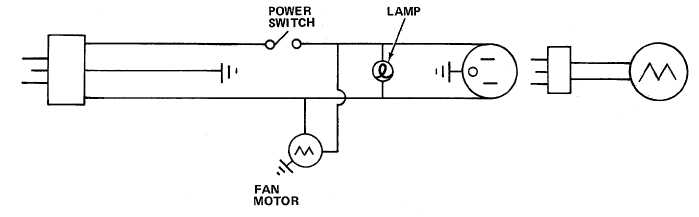

For unidentified malfunctions, use the following schematic or the foldout located at the end of this manual for

further fault analysis.

Table 4-3. ORGANIZATIONAL TROUBLESHOOTING

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

WARNING

Electrical shock hazard. You must stand on rubber matting as a protective measure

before performing these procedures. Death or serious injury could occur.

1.

FAN MOTOR DOES NOT OPERATE.

Step 1.

Check power outlet for 120 V ac using a multimeter.

(a)

If power is not present, proceed to step 2.

(b)

If power is present, replace dust control assembly (paragraph 4-16.2).

4-16