TM 5-6675-321-14

Table 4-2.

TROUBLESHOOTING - Cont

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

4.

COATING LAYER IS TOO THICK OR TOO THIN - Cont

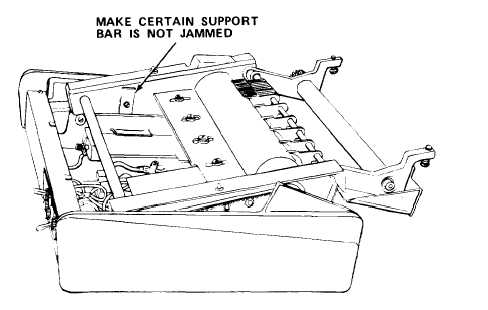

Step 2.

Check that coating roller is seated properly in wax and carriage

support bar is not jammed.

Push down on both ends of coating roller. Free carriage support

bar if jammed.

5. WAX COATING CONTAINS DUST PARTICLES OR DIRT.

Step 1.

Check that wax in tray is clear and has no suspended matter.

(a) If wax is clear, proceed to step 2.

( b ) D r a i n a n d r e p l a c e w a x.

Step 2.

Check that wax on coating roller is clear with no foreign particles.

C l e a n c o a t i n g r o l l e r .

4-29