TM 5-6675-302-14&P

WARNING

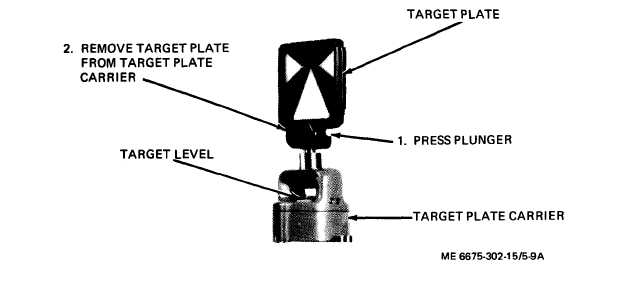

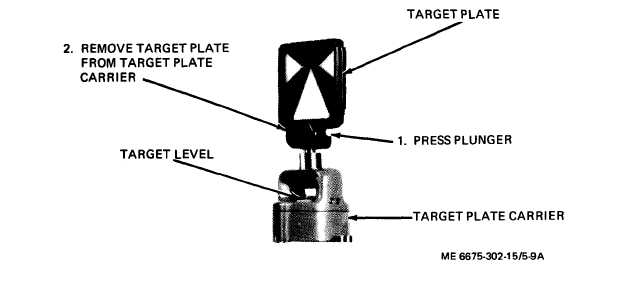

c. Reassembly. Refer to figure

5-16 and

(2) Install the tribrach assembly paragraph

reassemble the target plate carrier.

4-9.

e. Adjustment. If, after the circular level has

d. Installation.

been adjusted (para 5-8), the target level bubble is

far off center, the target level is out of adjustment,

(1) Refer to figure 5-14 and install the target

Tighten or loosen the adjusting screw (13, fig. 5-16)

plate on the target plate carrier.

to bring the bubble to center.

Figure 5-14. Target plate, model USATS-79, removal and installation

Section VI. REPAIR OF BATTERY BOX, HAND LAMP AND

ELECTRICAL CABLE, AND EYEPIECE ADAPTER ASSEMBLY

5-20. General. The illumination system consists

of a battery box, with a rheostat to control the in-

tensity of light illuminating the target. A hand

lamp that plugs into the battery box is also provid-

ed for general external lighting purposes. An

eyepiece adapter fits over the eyepieces and pro-

vides illumination for the optical plummet.

5-21. Battery Box.

a. Disassembly. Refer to figure 5-17 for model

242406 or figure 5-18 for model USATS-79, and

disassemble the battery box.

b. Cleaning, Inspection and Repair.

Clean parts in a well-ventilated area.

Avoid inhalation of solvent fumes and

prolonged exposure of skin to cleaning

solvent. Wash exposed skin thoroughly.

Dry cleaning solvent (Fed. Spec.

P-D-680) used to clean parts is potential-

ly dangerous to personnel and property.

Do not use near open flame or excessive

heat. Flash point of solvent is 100F to

138F (38C to 59C).

(1) Clean all metal parts with cleaning solvent

and dry thoroughly. Wipe all corrosion from ter-

minals and contacts. Wipe dirt and foreign matter

from cables, lamp trunk, springs, washers, and

rheostat.

(2) Inspect the cables and contacts for cracked,

swollen, or damaged insulation, broken wires, and

defective terminals. Inspect the springs for bends,

breaks, and fatigue.

(3) Inspect the lamp trunk for cracks and other

damage. Inspect the rheostat for improper opera-

tion and other damage. Inspect the sockets for

cracks and wear. Inspect the springs for bends,

and fatigue. Inspect the contacts and slide lever

for wear, burrs, and bends.

5-18