6-14

ARMY TM 5-6675-238-14

MARINE CORPS TM 08839A-14/1

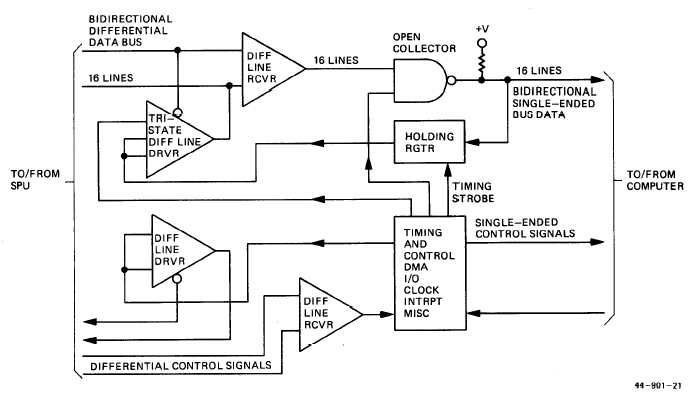

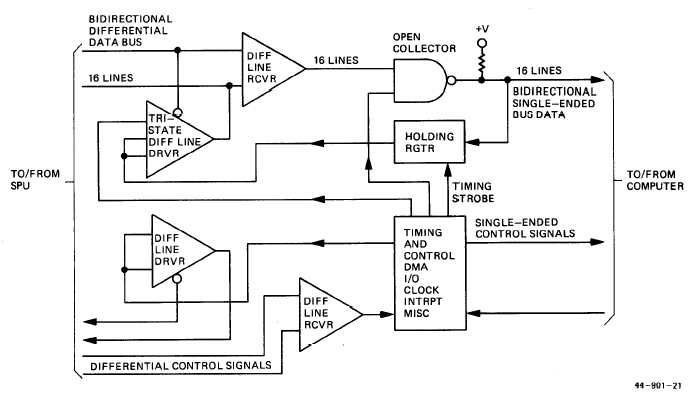

Figure 6-4. Buffer Unit Functional Block Diagram

transistor turns on, which causes the output transistor

to be turned off, producing an output voltage level

greater than +3.5V. For darkened inputs (no hole), the

input transistor is turned off causing the output transis-

tor to produce a voltage output of less than 0.8 VDE,

The light level at which the photocell amplifier

switches from off to on is determined by the setting of

the input bias potentiometer for each amplifier input.

The amplifier outputs are parallel transferred via con-

nector J2 to external using equipment. Amplifier out-

puts are also made available at test points located on

terminal board TB1.

c. Drive System and Control. The tape drive con-

trol system consists of pulse rate generator and logic

plug-in circuit card, forward/reverse control plug-in

circuit card, and two motor driver control plug-in

circuit cards used for drive and control of step motor

Bl. Also included is servo amplifier plug-in circuit card

which accepts constantly varying DC inputs for bidirec-

tional tape spooling control of spooling motors B2 and

B3. Spooling disable is provided by a switch mounted

on the front panel, This switch removes the +28V

from all internal circuits, disabling the spooling and

stopping functions. This allows removal and installation

of the tape while external power is applied to the tape

reader.

d. Step/Run Control. When a step command is

applied to the pulse rate generator and logic plug-in

circuit card, a negative-going output step trigger is

generated. This action continues at the external step

rate, provided the run input is at 0V. The step trigger is

applied to both motor driver control plug-in circuit

cards. In addition, a reverse signal is developed and

imported to the forward/reverse control plug-in circuit

card. When the external forward input control signal is

at 0V, the output signal levels of the forward/reverse

control logic are the same as the input, and the forward

sequencing condition exists, When the input control

signal is at + 5V, the output signal levels are inverted

and the reverse sequencing condition exists. The alter-

nating output levels are applied to the set and clear

inputs of the flip-flops on each motor driver card, The

flip-flops are constrained by the input gating action and

provide the correct sequence of output pulses to step

the stepping motor in the forward direction (counter-

clockwise sprocket rotation) or in the reverse direction.

The flip-flop output from each motor driver card and

the step trigger pulse provide control and drive to

motor driver output circuits, The motor driver outputs

are connected to the windings of step motor Bl.

e. Forward/Reverse Control. In the forward mode

of operation, power is applied to servo feedback poten-

tiometers R2 and R3 in a direction to supply a servo

drive input voltage to an associated servo amplifier

circuit on servo amplifier plug-in circuit card. The

input is proportional to the amount of tape on the reels

as controlled by the movement of each tape sensing