TM 5-3610-253-14

e. Safety bolt assembly. Prevents the knife from making more than one cut at a

time. The safety bolt is controlled by a solenoid. When the solenoid is de-energized,

a spring forces the safety bolt out of the solenoid. The safety bolt is then in a

position which prevents the knife carrier from moving downward. When the solenoid is

energized, the safety bolt is retracted, allowing the knife carrier to move downward.

The solenoid is controlled by the hardware channel (HK) board in the control unit.

When the cutting buttons are depressed, and the knife delay is over, the solenoid is

energized, and the safety bolt retracted, allowing the knife carrier to move down-

ward. When the knife carrier reaches the bottom of its stroke, the safety bolt

solenoid is de-energized. This forces the safety bolt against the back of the knife

carrier. Once the knife carrier reaches the top of its upward stroke, the safety bolt

is then clear of the back of the knife carrier and is allowed to extract fully. This

keeps the knife from making a second cut. The safety bolt can only be retracted

again by releasing the cutting buttons and depressing them. On the back of the safety

bolt are two proximity switches (B.SBE and B.SBA). The proximity switches are

magnetically activated. When the safety bolt is fully extracted, proximity switch

(B.SBE) is closed, and proximity switch (B.SBA) is opened. When the safety bolt is

fully retracted, proximity switch (B.SBE) is opened, and proximity switch (B.SBA) is

closed.

f. Lighting system. Provides illumination of the work surfaces and controls.

There are two illumination devices on the machine.

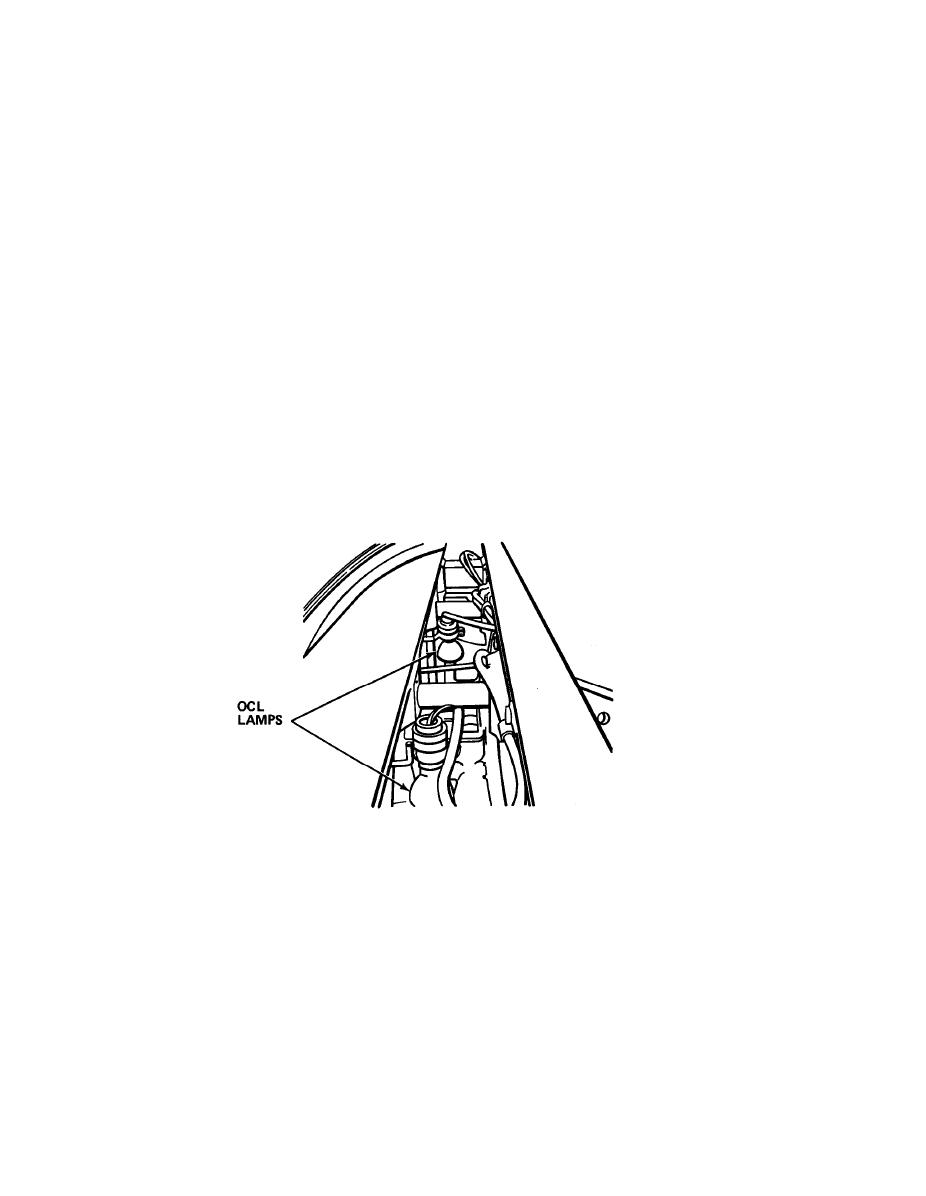

(1) OCL lamps. Two lamps within the top frame of the machine. They shine

between the knife carrier and the clamp to produce a thin cutting line on the table

bed. The line shows where the knife will cut when it comes down so that material to

be cut can be properly positioned. The position of the lamps can be adjusted via two

knurled knobs on the back of the frame to produce the best cutting line.

5-317