TM 5-2330-305-14

4. Remove valve from air line.

5. Clean all threaded parts with solvent-saturated, cotton cloth.

CAUTION

DO NOT ALLOW EXCESS SEALANT TO ENTER

AIR LINES. SEALANT MAY OBSTRUCT AIR

LINE IF INTRODUCED INTO AIR SYSTEM.

6. Apply sealant to air line threads and install new valve.

7. Apply sealant to threads of elbow and reinstall into valve.

8. Reinstall hose and tighten securely.

9. Check for leaks by pressurizing system, applying soapy water

solution to fittings and inspecting for presence of air bubbles.

4.4.1.14 REPLACE AIR SPRING.

TOOLS: Tool Kit

Torque Wrench (0-150 ft lbs)

SUPPLIES: Air Spring

CAUTION

BE SURE CHASSIS IS PARKED ON LEVEL GROUND

AND IS UNHOOKED FROM TRUCK BEFORE PROCEED-

ING TO PREVENT PERSONNEL INJURY.

1. Extend chassis leveling jacks to raise chassis high enough to

relieve tensin on air spring.

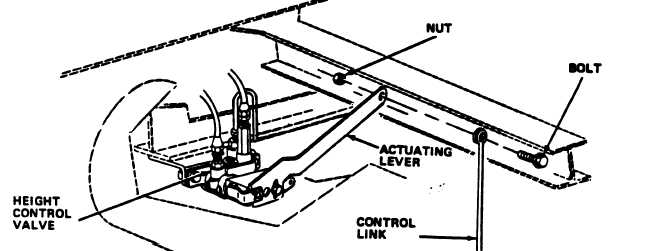

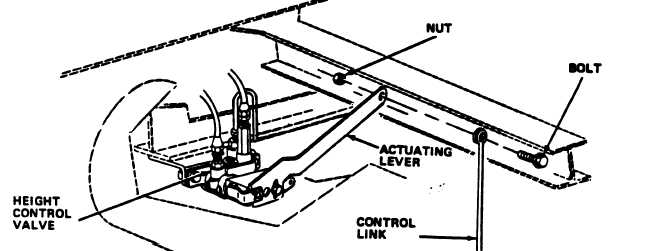

2. Remove nut and bolt which secure control link to height control

valve actuating lever.

4-31