ARMY TM 9-1290-262-24&P

MARINE CORPS TM 00476C-24&P

AIR FORCE TO 49A7-3-72/74

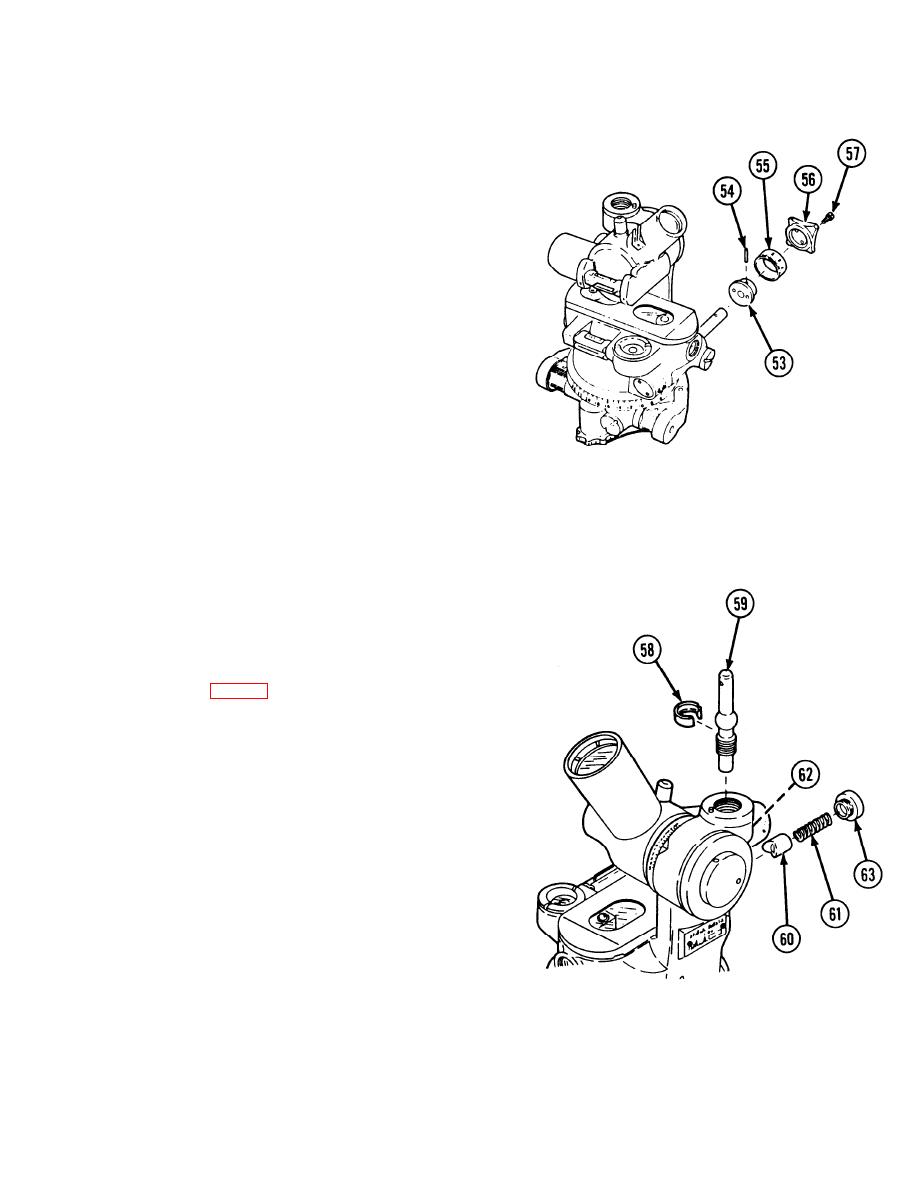

Install flat washer (52) and adapter (53) on

52

worm shaft (44). Aline adapter pin hole

with pin hole in shaft and install taper pin

(54).

NOTE

If a new worm was installed, perform

steps 53 thru 55 as follows:

Position scale dial (55) over adapter (53)

53

and push toward azimuth index (51).

Leave a clearance of no more than 0.015

in. (0.381 mm) between scale dial and

azimuth index.

Remove scale (55), but do not move

54

adapter (53).

Using hole in adapter (53) as a guide, drill

55

a No. 52 hole in worm shaft and ream for

No. 6/0 pin. Install pin (54).

Install scale dial (55), knob (56), and two

56

screws (57). Do not tighten screws until.

after collimation adjustment.

Lightly lubricate ball socket seat (58),

57

worm shaft (59), sleeve bushing (60),

spring (61), and all bearing and working

surfaces inside body assembly with grease

(item 6, appx D).

Place ball socket seat (58) on worm side

58

of ball, alining slot in ball socket seat with

setscrew hole in housing.

To install worm shaft (59) in body assem-

59

bly, push in and rotate worm onto internal

gear until ball socket seat (58) is in place

within body assembly.

Check that slot in ball socket seat (58) is

60

still alined with setscrew hole in body as-

sembly.

NOTE

Setscrew (62) will be tightened during

backlash adjustments.

Install sleeve bushing (60), spring (61),

61

and machine thread plug (63). Tighten

machine thread plug (63) securely.

3-23