TM 5-6675-328-14

SECTION IV ORGANIZATIONAL MAINTENANCE

5-11. LUBRICATION INSTRUCTIONS.

NOTE

These lubrication instructions are mandatory.

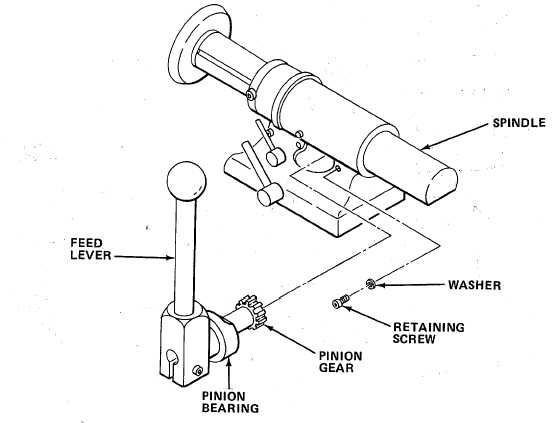

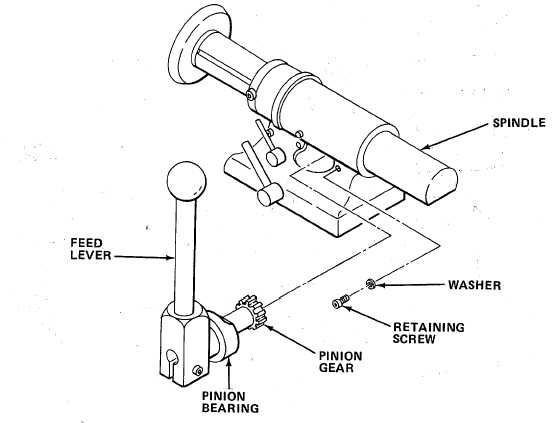

5-11.1. Tailstock Spindle. After removing the retaining screws, washers, and feed lever, apply a thin film of grease (Item

8, Appendix E) on the pinion and spindle. Apply a light coat of oil (Item 10, Appendix E) on the pinion bearing. Wipe off

any excess with clean cloth and reinstall feed lever. This should be done on a monthly basis.

5-12. REPAIR PARTS, SPECIAL TOOLS; TEST, MEASUREMENT, AND DIAGNOSTIC EQUIPMENT; AND

SUPPORT EQUIPMENT.

5-12.1. Common Tools and Equipment. For authorized common tools and equipment, refer to the Modified label of

Organization and Equipment (MTOE) applicable to your

unit.

5-12.2. Special Tools; Test, Measurement, and Diagnostic Equipment; and Support Equipment. No special tools; test,

measurement, and diagnostic equipment; or sup- port equipment are required for the repair of this equipment at the

organizational level of maintenance.

5-19