TM 5-6675-328-14

Table 5-1. OPERATOR PREVENTIVE MAINTENANCE CHECKS AND SERVICES - Cont

B - Before

W - Weekly

AN - Annually

(Number) - Hundreds of Hours

D - During

M - Monthly

S - Semiannually

A - After

Q - Quarterly

BI - Biennially

ITEM TO BE INSPECTED

For Readiness

ITEM

IN-

Reporting,

NO.

TER-

Equipment Is

VAL

PROCEDURE

Not Ready/

Available If:

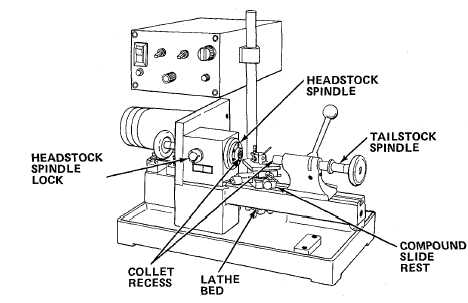

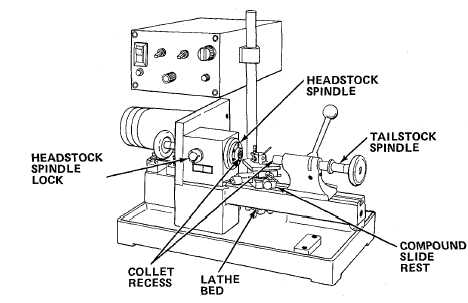

INSTRUMENT LATHE - Cont

1

A

Inspect Lathe - Cont

3. Inspect bearing surfaces for cleanliness. All surfaces must be free of dust,

dirt, or other residue and properly lubricated with lubricating oil before any

part of machine is operated (paragraph 6-8).

4. Inspect headstock spindle lock for proper operation. Refer malfunctioning

spindle lock to organizational maintenance.

5. Inspect chip screen for residue and clean with cheesecloth.

6. Check tailstock spindle, feed lever, and bed lock for proper operation.

2

B/A

Service Lathe.

1. Clean chips from lathe bed surface.

2. Clean chips from compound slide rest with cheesecloth.

5-11