TM 5-6675-323-14

NOTE

I f the equipment must be kept in continuous operation, check and service

only those items that can safely be checked and serviced without dis-

t u r b i n g o p e r a t i o n . M a k e the complete checks and services when the

e q u i p m e n t can be shut down.

AN - Annually

W - Weakly

B - Before

(Number) - Hundreds of Hours

S - Semiannually

M - Monthly

D - During

BI - Biennially

Q . Quarterly

A - After

For Readiness

ITEM TO BE INSPECTED

IN

Reporting,

lTEM T E R

Equipment Is

PROCEDURE

NO VAL

Not Ready/

Available If:

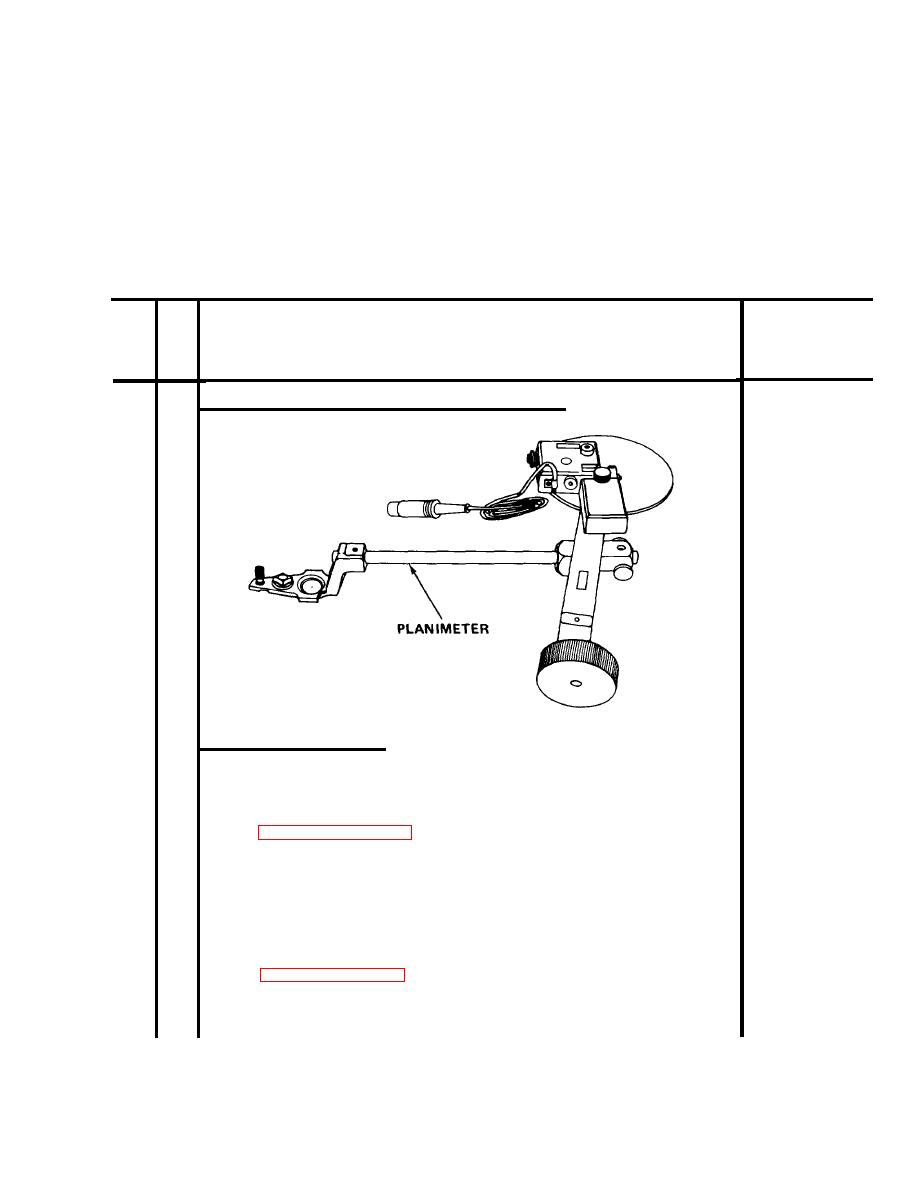

QUANTITY PROCESSING SYSTEM (PLANIMETER)

1

Inspect

Planimeter.

B

Components

1.

C h e c k wheels, lens tracing assembly, axle, and

are dirty

paper disk for dirt, cracks, and breaks. Clean

or broken.

w i t h s o f t b r u s h . R e p l a c e paper disk as needed

D r i v e gears

Check planimeter drive gears for dirt or

2.

are damaged.

breaks.

Check for jammed or loose drive gears.

Teflon guide

3.

C h e c k teflon guide washer underneath tracing lens

w a s h e r is

for cracks, dirt, or looseness. Clean with soft

dirty or

brush.

R e p l a c e teflon guide washer as needed

cracked.

9-29