TM 5-6675-316-14

NOTE

The lighter the material, the lower the temperature should be set to pre-

vent bleed-through.

The higher the temperature, the greater the possibili-

ty of bleed-through.

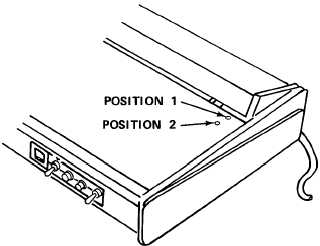

c.

Set LOW/HIGH thermostat to 1 position if material to be coated is normal-

weight stock.

If material is lightweight, set thermostat lower.

CAUTION

If wax level is allowed to fall below mark, damage to machine may result.

d. Check wax level in tray.

Add piece of wax if below level indicator.

e.

Position top deck cover on wax coater by placing cover holes over pins. If

coating lightweight or normal weight stock, place cover all the way forward (posi-

tion 1).

For heavier materials, place cover back one hole (position 2).

f. Turn MAIN switch ON.

If HEAT ON pilot light does not come on, refer to

troubleshooting procedures.

9.

Allow time for wax to melt, approximately 15 to 18 min.

8-25