TM 5-3610-285-14

Table 5-1. OPERATOR PREVENTIVE MAINTENANCE CHECKS AND SERVICES - Cont

B - Before

W - Weekly

AN - Annually

(Number) - Hundreds of Hours

D - During

M - Monthly

S - Semiannually

A - After

Q - Quarterly

BI - Biennially

ITEM TO BE INSPECTED

For Readiness

IN

Reporting

ITEM

TER-

PROCEDURE

Equipment Is

NO.

VAL

Not Ready/

Available If:

FILM PROCESSOR - Cont

19

Q

Inspect Flowmeters and Check Flow Rates - Cont

3.

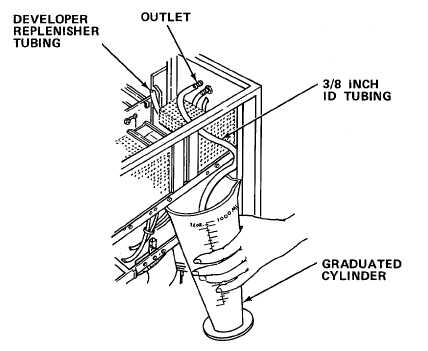

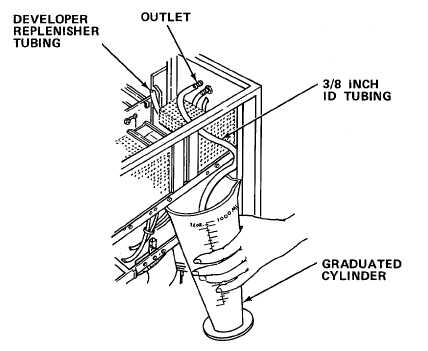

Disconnect developer replenisher tubing from

outlet of flowmeter and fasten this tube to

processor so that open end is above solution

level in tank, as shown.

4.

Attach a 5 ft (1.5 m) piece of 3/8 in.

(9.53 mm) ID tubing to outlet of flowmeter.

Put end of tube in graduated cylinder.

Turn on replenisher pump (REPL PUMP switch

to MANUAL) momentarily to remove any air

from line.

NOTE

Always use the center of the flowmeter ball as a reference point.

5-43