TM 5-3610-253-14

b. Sledge. Moves on ground guides in table slot. Driven by table spi ndle, it

protrudes through the table slot and connects to backgauge.

c. Backgauae. Rests on the table top. Connected to the sledge and moves with

the sledge. Adjustable to maintain parallelism and squareness with cutting knife.

d. Backgauge rake. Three piece cast structure mounted to front of backgauge.

Lower sides of rake are ground at an angle and spring loaded to prevent material

from escaping under rake fingers. The left and right rakes are adjustable (forward

or backward) to allow for setting of three different measurements at one time.

Backgauge control knob. Controls movement of backgauge (forward and

backward) both electrically and mechanically. Pull knob out or press button in to

move the backgauge automatically. When the knob is pressed inward, it engages a

gear on the table spindle. Rotating the knob manually rotates the gear, which moves

the backgauge.

f. Backgauge brake. Rapidly stops spindle rotation when backgauge control knob

is released (paragraph 5-3.6i).

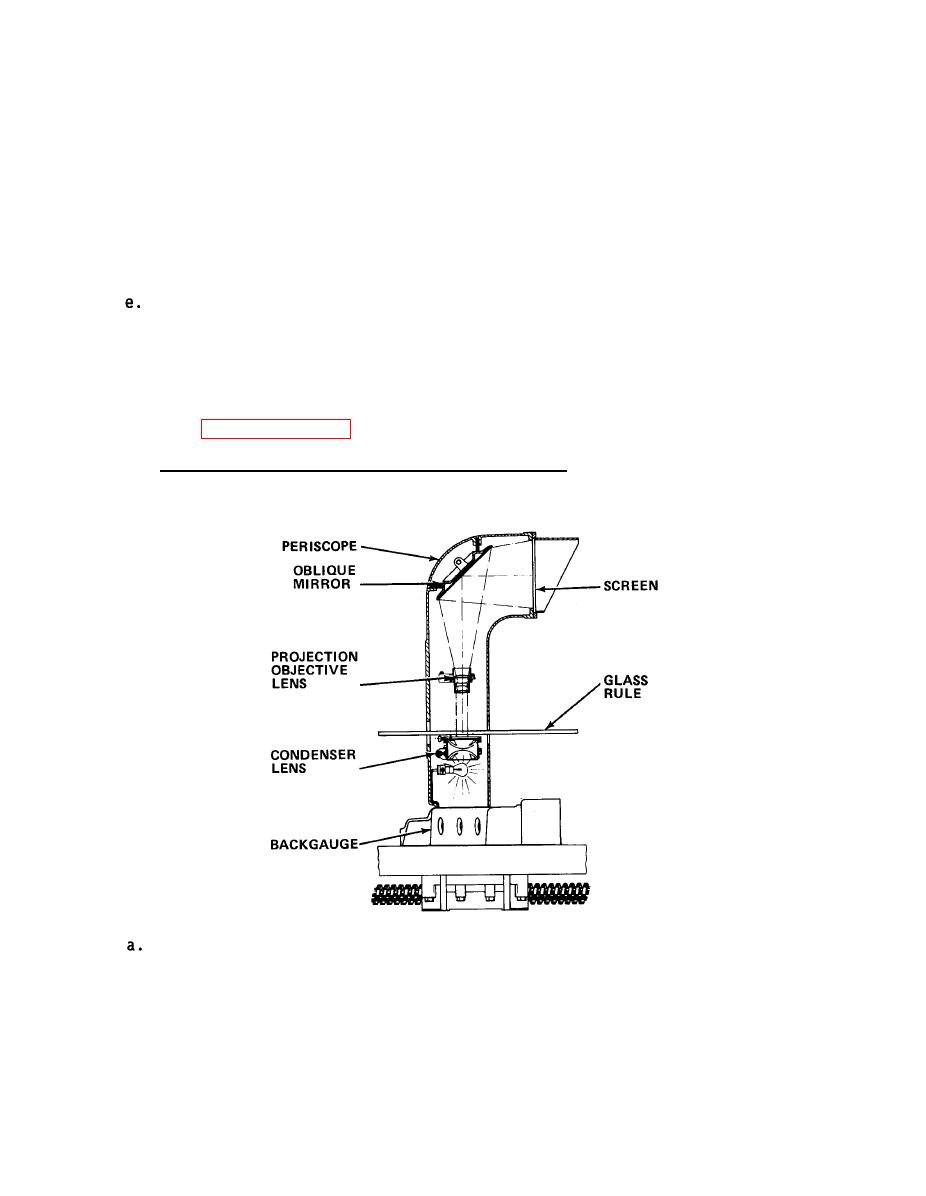

5-3.4 Optical Measurement Indicator (OMI) Assembly. Moves synchronously with back-

gauge rake to give direct measurement indication of the distance from the backgauge

rake to the knife cut. It is comprised of:

Glass rule. Transparent glass rule scaled in inches. It is clamped at the

back of the machine frame and the end of the table. It runs through the middle of

the periscope housing. The measurement mark on the rule is projected onto the OMI

screen, giving the distance from the front edge of the backgauge rake to the cutting

line.

5-9