TB 1-4920-443-35

AEDATS IV T64 ALIGNMENT WORKSHEET

1. AEDATS IV T64 Alignment Worksheet

NOTE

Ensure system is in the mode for the engine requiring alignment (T64)

a. Angle Position Measurement System

(1) Dyno shroud Position Indicator

(Refer to pages 85 step 66) Connector P91 (F+) (H-)

(a) Input the following voltages into Connector P91

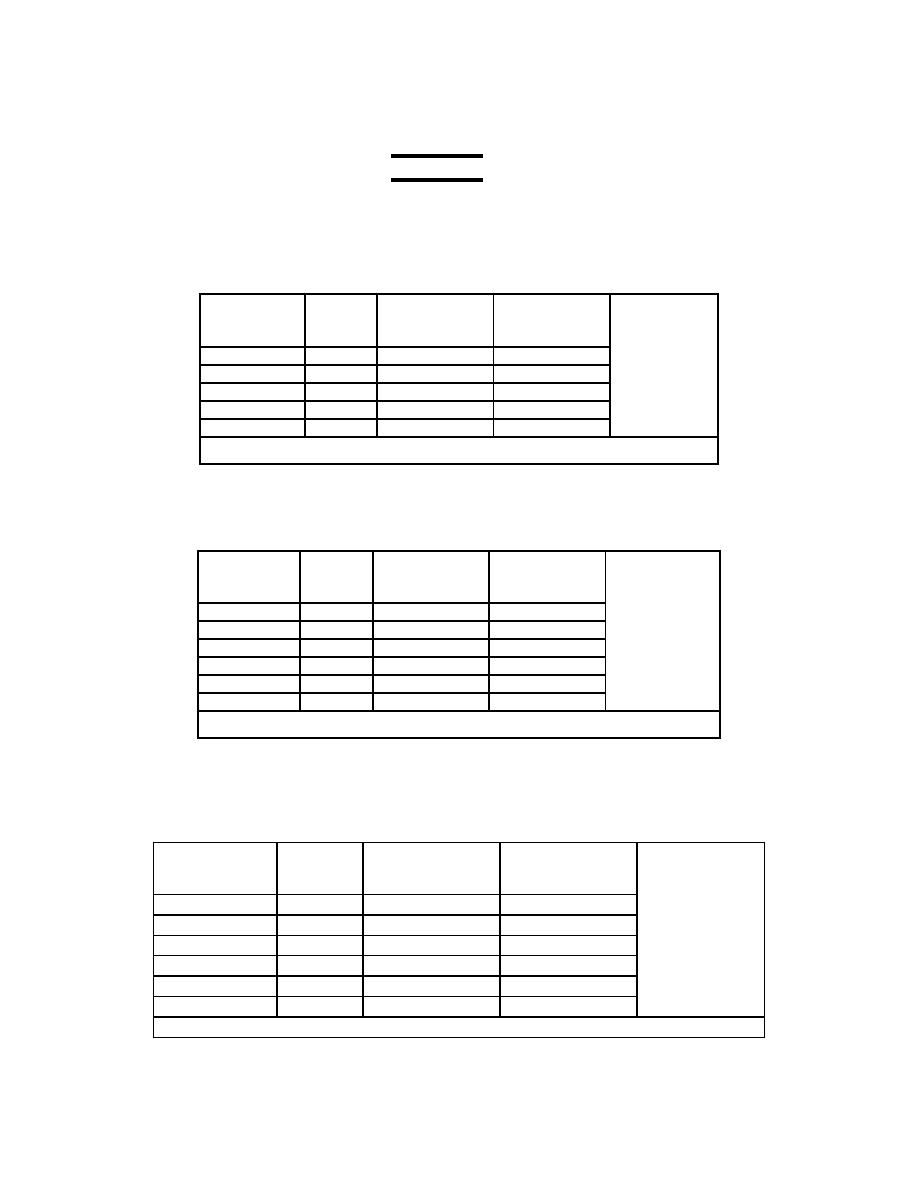

Vertical Scale

Input Voltage

Percent

AEDATS 4

Vertical Scale

Bottom row 3

Reading

(DynoShrd)

+/-.1%

+/-.5%

0 volts

0%

____________

____________

4 volts

25%

____________

____________

8 volts

50%

____________

____________

12 volts

75%

____________

____________

16 volts

100%

____________

____________

Transducer: T77 Hardware Name: HL34

(2) Power Lever Spindle Position (T64)

(Refer to pages 83 step 64)

(a) Input the following voltages into connector P51 pins A (+) and B (-).

(b) Connector P51 at Engine (LOADLVR)

Vertical Scale

Input voltage

Degrees

AEDATS 4

Vertical Scale

Bottom Row 2

+/- 1.0 deg

(THROTTLE)

+/- .5 deg

0 volts

0

____________

____________

2.4volts

30

____________

____________

4.8volts

60

____________

____________

7.2 volts

90

____________

____________

9.6 volts

120

____________

____________

12 volts

150

____________

____________

Transducer: T81 Hardware Name: HL35

(3) Load Demand Spindle Position (T64)

(Refer to pages 82 step 63)

(a) Ensure the T1 Load Lever amplifier is installed

(b) Input the following voltages into connector P50 pins A (+) and B (-).

(c) Connector P50 at Engine (LDS)

Vertical Scale

Input Voltage

Degrees

AEDATS 4

Vertical Scale

Bottom row 1

(THROTTLE )

+/- 1.0 deg

+/- .5 %

0 volts

0

____________

____________

1.6 volts

20

____________

____________

3.2 volts

40

____________

____________

4.8 volts

60

____________

____________

6.4 volts

80

____________

____________

8.0 volts

100

____________

____________

Transducer: T82 Hardware Name: HL36