TM 5-6675-325-14

Table 5-1. OPERATOR PREVENTIVE MAINTENANCE CHECKS AND SERVICES

NOTE

If the equipment must be kept in continuous operation, check and service

only those items that can safely be checked and serviced without dis-

turbing operation.

Make the complete checks and services when the

equipment can be shut down.

B - Before

W - Weekly

AN - Annually

D - During

(Number) - Hundreds of Hours

M - Monthly

- Semiannually

A - A f t er

Q- Quarterly

BI

- Biennially

ITEM

No.

1

B

ITEM TO BE INSPECTED

PROCEDURE

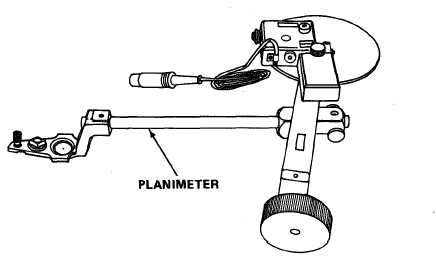

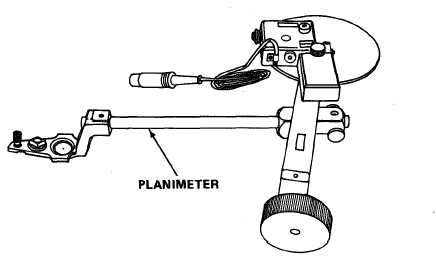

QUANTITY PROCESSING SYSTEM (PLANIMETER)

lnspect Planimeter.

1.

2.

3.

Check wheels, lens tracing assembly, axle, and

paper disk for dirt, cracks, and breaks. Clean

with soft brush.

Replace paper disk as needed

(paragraph 5-10.4).

Check planimeter drive gears for dirt or

breaks.

Check for jammed or loose drive gears.

Check teflon guide washer underneath tracing lens

for cracks, dirt, or looseness. Clean with soft

brush.

Replace teflon guide washer as needed

(pararaph 5-10.2).

For Readiness

Reporting,

Equipment Is

Not Ready/

Available If:

Components

are dirty

or broken.

Drive gears

are damaged:

Teflon guide

washer is

dirty or

cracked.

5-29