TM 5-6675-316-14

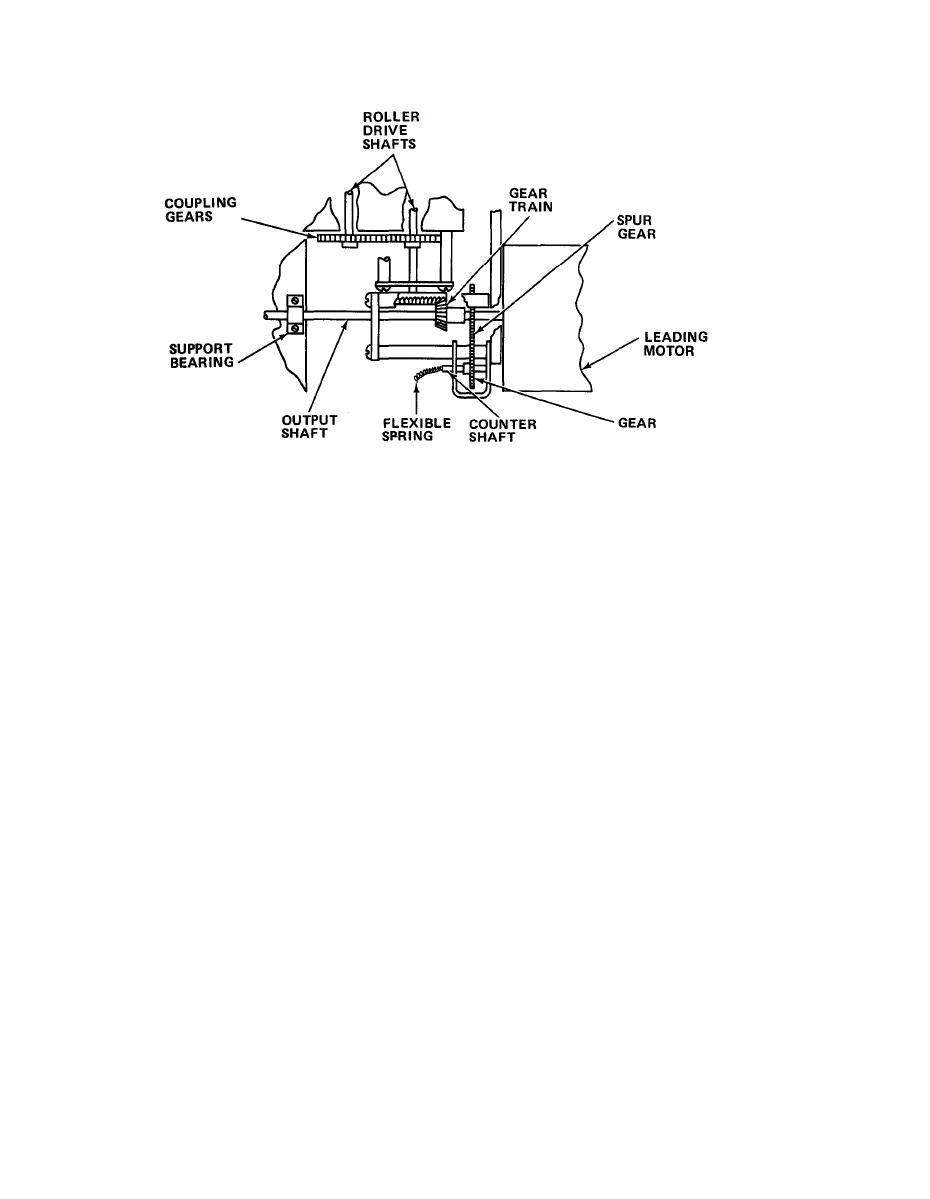

(2) The film drive or leading motor has a long output shaft. The shaft is

extended through the support bearing to a knob which is used for manual film

advance. The spur gear rotates with the main shaft, turning the gear. This gear is

fixed to the counter shaft. The rotation is transferred via the flexible spring to

a mechanical digital display which shows the quantity of film that has been used.

The roller drive is taken through the 90-degree gear train to two coupling gears and

to the roller drive shafts. The stepping motor operates in 0.007 in. (0.177 mm)

steps, as controlled via the main program.

(3) Four constant current Darlington driver circuits supply the four leading

motor coils to step the motor. The drivers are controlled by signals from the LVC

(Low Voltage Control) stepper board, a fifth signal is used to switch the current to

the coils from full to half when the motor is not stepping.

2-20