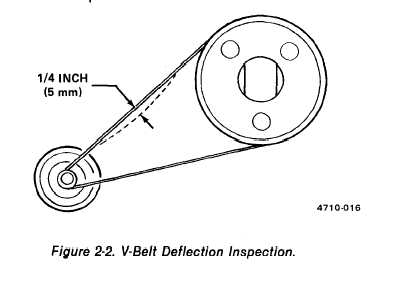

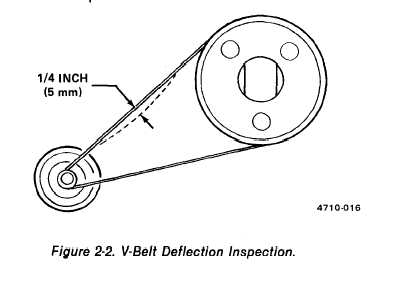

Figure 2-2.

TM 5-3610-286-20

Table 2-1. Organizational Preventive Maintenance Checks and Services (PMCS) (cent).

M – Monthly

Q - Quarterly

S - Semiannually

A - Annually

Interval

Item

Item to be

No.

M

Q

S

A

inspected

Procedures

8

l

Main Motor

Remove motor covers and vacuum clean of dust

(refer to para. 2-79).

9

l

Main Motor Brushes

Check for wear, brush pressure, and movement of

commutator brushes in holder (refer to para. 2-

79). Check for firmness of contact between lead

and brush (on commutator side) and between

brush and brush holder (on slipring side). Re-

place commutator-carbon brushes when they are

worn to a length of 0.39 in. (10 mm). Replace

slipring brushes when running edge protrudes

0.79 to 1.18 in. (2 to 3 mm) over lower retaining

rim (refer to para. 2-79).

10

l

V-Belt

Check for loose or worn V-belt. Place a straight

edge against motor pulley and flywheel. Check for

approximately 1/4" (5 mm) deflection. If too loose

or too light, adjust V-belt (refer to para. 2-80).

2-7