TM 5-3610-257-14

d.

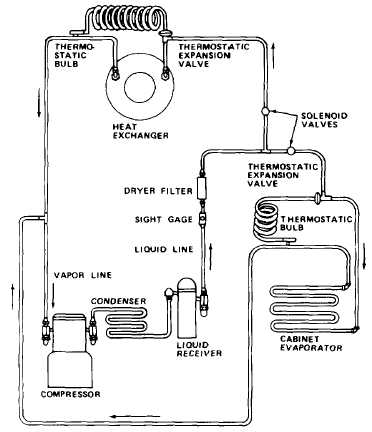

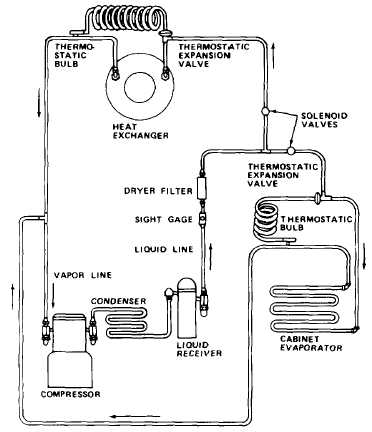

Sight gage. Indicates if freon lines are charged to capacity. With compressor running, a solid stream of liquid

refrigerant should be visible in the glass sight gage. If bubbles are present, the system is not fully charged.

e.

Dryer filter. Removes moisture from liquid refrigerant lines between liquid receiver and thermostatic expansion

valves.

f.

Solenoid valves. Controls liquid refrigerant flow to heat exchanger and cabinet evaporator coils.

9.

Thermostatic expansion valve. Thermostatically and pressure-regulated ball valve creates a pressure drop in

refrigerant flow. The pressure drop changes the refrigerant from liquid to gas, and heat is absorbed during the process.

h.

Cabinet evaporator. Located in the refrigeration cabinet. Its coils absorb heat from the cabinet. The evaporator

coils contain refrigerant which is vaporized by an expansion valve.

i.

Heat exchanger. Contains evaporator coils inside a solid housing which absorb heat from water pumped through

housing. The evaporator coils contain refrigerant which is vaporized by an expansion valve. The heat exchanger also

contains an immersion-type resistance heater to warm the water if temperature is too low.

5-3.2.

Recirculating System. Provides a temperature-controlled water bath to maintain a proper processing

temperature for processing solution trays located in the sink. It consists of a magnetic-drive, centrifugal pump which

recirculates water from the sink, through the heat exchanger, and back to the sink.

5-4