TM 5-6675-321-14

b .

This manual cannot list all

inspection and corrective action.

l i s t e d c o r r e c t i v e a c t i o n , n o t i f y

t h e p o s s i b l e m a l f u n c t i o n s o r e v e r y p o s s i b l e t e s t /

I f a m a l f u n c t i o n i s n o t l i s t e d o r c o r r e c t e d b y a

your supervisor.

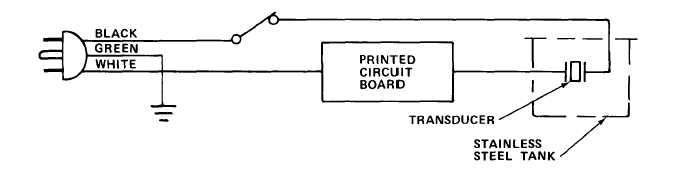

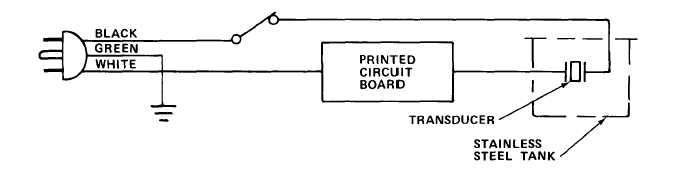

c . F o r u n i d e n t i f i e d m a l f u n c t i o n s , u s e t h e f o l l o w i n g s c h e m a t i c o r t h e f o l d o ut

l o c a t e d t h e e n d o f t h i s m a n u a l f o r f u r t h e r f a u l t a n a l y s i s .

d.

If the ultrasonic cleaner does not power up when turned on, verify that 120 v

ac is present at the receptacle .

I f v o l t a g e i s n o t p r e s e n t , p l u g e q u i p m e n t i n to

receptacle with power available and proceed with equipment troubleshooting.

Perform

no - power procedure for dead receptacle (Table 1 - 4).

Table 5-2. ORGANIZATIONAL TROUBLESHOOTING

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1.

NO CLEANING ACTION, WATER AGITATES.

Check cleaning action using fresh cleaning solution .

( a ) I f t e s t w a s s a t i s f a c t o r y , i n s t r u c t o p e r a t o r t o c h a n g e c l e a n i ng

solution when dirty.

(b) If test was not satisfactory, replace circuit board (paragraph

5-16.3).

2 .

NO WATER AGITATION.

Step 1.

U s i n g m u l t i m e t e r , c h e c k f o r c o n t i n u i t y o f p o w e r c o r d .

( a ) I f c o n t i n u i t y e x i s t s , p r o c e e d t o s t e p 2.

(b)

If

continuity

does

not

exist,

replace

power

cord

(paragraph

5-16.1)

5-10