TM 5-6675-315-14

d.

Inject sprayfoam into puncture. Mound sprayfoam to about 1/8 in. (3.2 mm) above surface of unbroken skin.

Apply bead of sealant about 1/4 in. (6.4 mm) wide over all cuts in skin leading out from puncture. Do not

smooth out sealant.

e.

Plan how puncture is to be covered with tape before applying any tape. Length and width of tape, number of

tape strips, overlapping, and how tape is applied will affect sealing capability of repair. Each piece of tape

should extend about 1-1/2 in. (38.1 mm) beyond sealant it will cover. If this will require more than one strip

of tape, tape should overlap about 1/2 in. (12.7 mm). If three or more strips of tape are required, center strip

should be applied first.

f.

Apply tape, holding it taut, and apply it perpendicular to panel skin. Do not apply with rolling motion either

end-to-end or center-to-ends. Do not rub each strip in place individually. Apply all strips lightly with proper

overlap and rub into place.

g.

If necessary, damaged tape can be replaced; however, it should be removed with careful peeling motion to

avoid damage to sealant. If sealant also peels back, new sealant should be applied. Complete removal of

old sealant is not necessary. Permanent repair by direct support, or higher category of maintenance, should

be made as soon as possible.

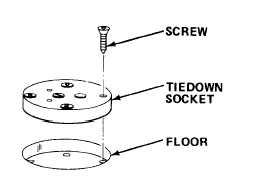

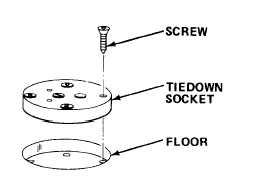

1-16.14 Replace Tiedown Socket.

MOS:

83FJ6, Reproduction Equipment Repairer

TOOLS:

Cross Tip Screwdriver

Flat Tip Screwdriver

SUPPLIES: Tiedown Socket

a.

Remove screws from tiedown socket.

b.

Pry defective socket from floor.

c.

Install new tiedown socket. Rotate new tiedown socket enough to avoid installing screws in old screw holes.

d.

Reinstall screws.

1-80